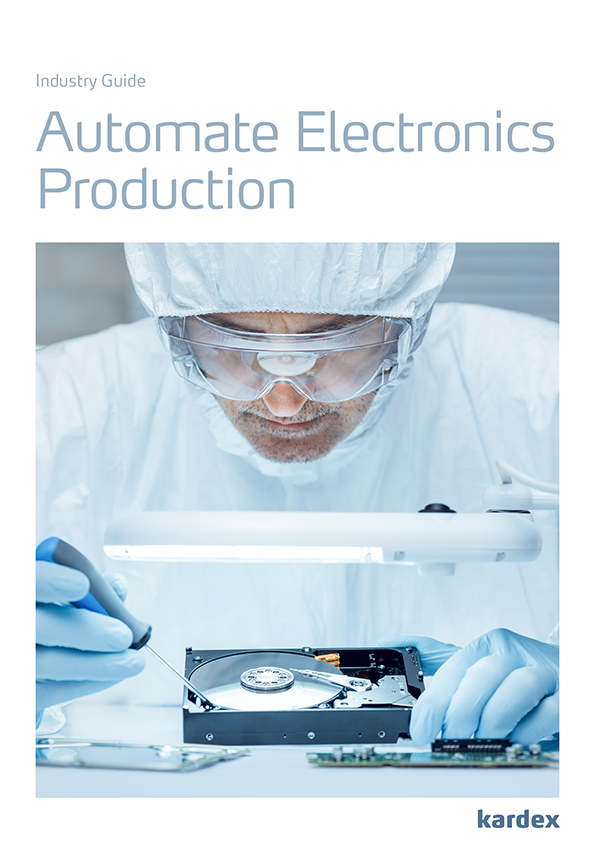

Electronics

Kardex offers tailored solutions for the electronics industry, including comprehensive ESD protection and controlled storage options for electronic components and SMD reels.

Find out below how Kardex finds the right solutions to various operational challenges and optimises intralogistics processes.

Challenges in the electronics industry

- Dust free stroage

- SMD reel storage, Return, and sequencing of the used reels

- FIFO

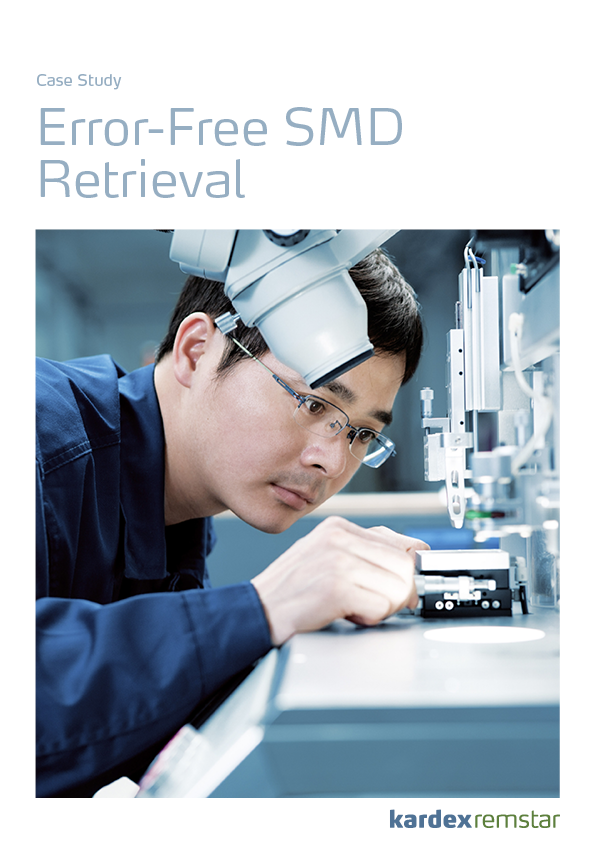

- Too many picking errors

- Sensitive to moisture

- Climate control

- Digitally integrated supply chain

System features

- Fire protection

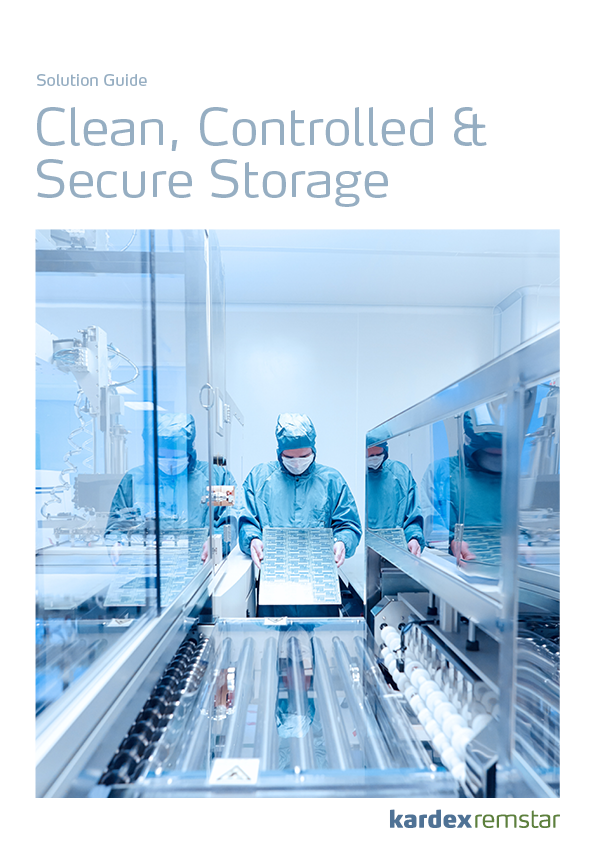

- Controlled environments

- Laser pointers

- Pick-to-light

- ERP connectivity

- Power Pick Global

Kardex systems are perfect for all products. No matter which loads, heights, or sizes, we will find a suitable solution for your needs.

Protect your stored goods against dirt, dust, and other external influences. We understand your needs and that sometimes it’s necessary to integrate different solutions for different articles and sometimes it’s necessary to create one solution for all articles.

Kardex systems offer an optional climate function that permits storing goods at constant temperatures ranging from -25°C to 60°C. It is also possible to reduce humidity in the units by up to 5%.

Customer benefits

-

SMD handling

Extremely flexible and constantly adapts to SMD reels in various dimensions.

-

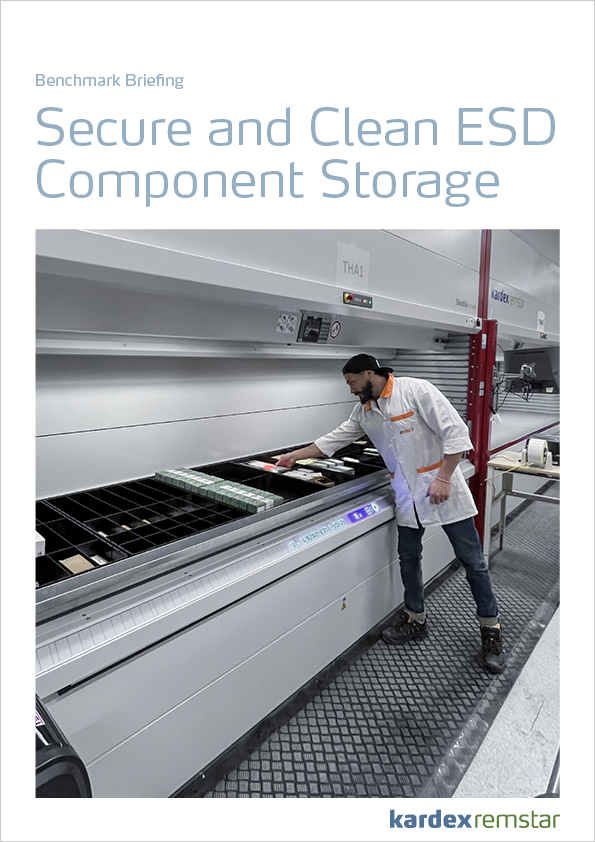

ESD-protected

Kardex systems offer an optional ESD-protected area.

-

Accurate inventory management

Permits the permanent monitoring of stock levels in real-time via a direct link to the Enterprise Resource Planning (ERP) system.

-

Dust-free storage

Meets the requirements necessary for cleanroom conditions.

-

Climate controlled

When storing sensitive items, regulate the humidity and temperature.

-

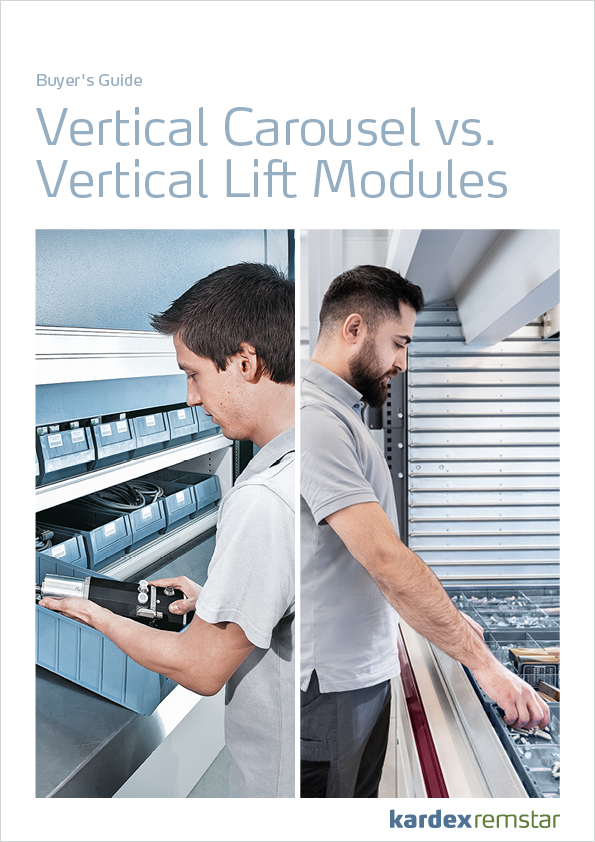

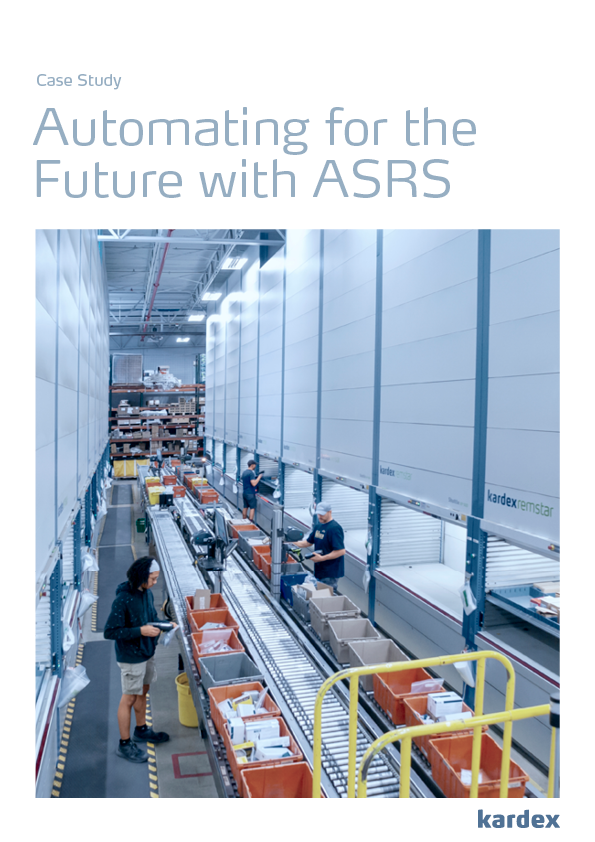

Less space needed

Highly-dense - reduces footprint size up to 85 %. Store the same amount in an area 10 - 25 % the size of its original space.

SMD handling

Extremely flexible and constantly adapts to SMD reels in various dimensions.

ESD-protected

Kardex systems offer an optional ESD-protected area.

Accurate inventory management

Permits the permanent monitoring of stock levels in real-time via a direct link to the Enterprise Resource Planning (ERP) system.

Dust-free storage

Meets the requirements necessary for cleanroom conditions.

Climate controlled

When storing sensitive items, regulate the humidity and temperature.

Less space needed

Highly-dense - reduces footprint size up to 85 %. Store the same amount in an area 10 - 25 % the size of its original space.

Useful Resources

Case studies

Van Meter, an electronics parts distributor, recently completed a warehouse automation project, and have since then increased labour efficiencies by 21%, throughput by 25% and raised picking accuracy up to 99.99%!