Smart Intralogistics for Manufacturers

The modern warehouse for manufacturers

In order to stay ahead, manufacturing warehouses must implement modern, automated intralogistics solutions. Facilities with outdated technology, inflexible systems, and poor inventory visibility will struggle to stay competitive in today's marketplace.

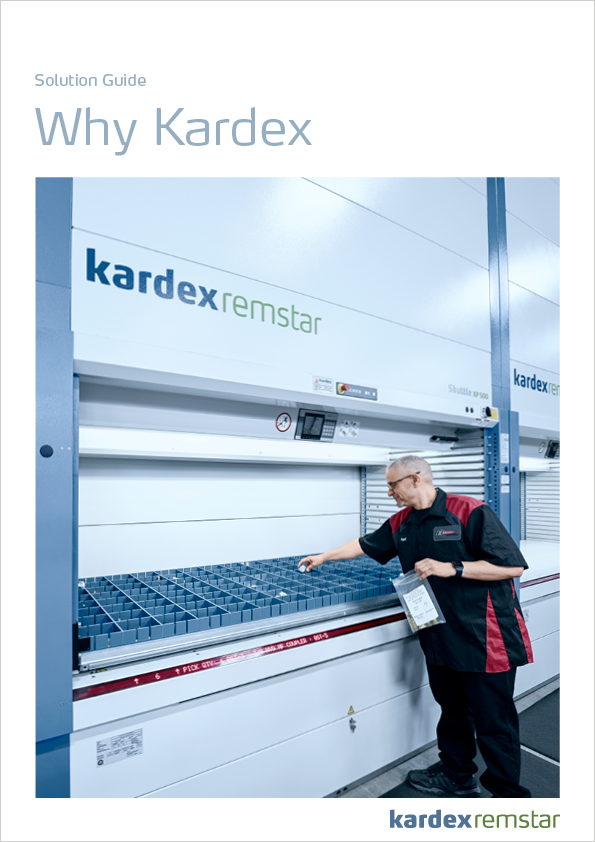

Kardex’s automated solutions are fast, reliable and designed to meet unique industry-specific challenges in manufacturing.

Gain advice from industry experts and see how the latest automated warehouse solutions can:

- ensure fast, reliable and secure access to production parts

- avoid supply chain bottlenecks and production downtime

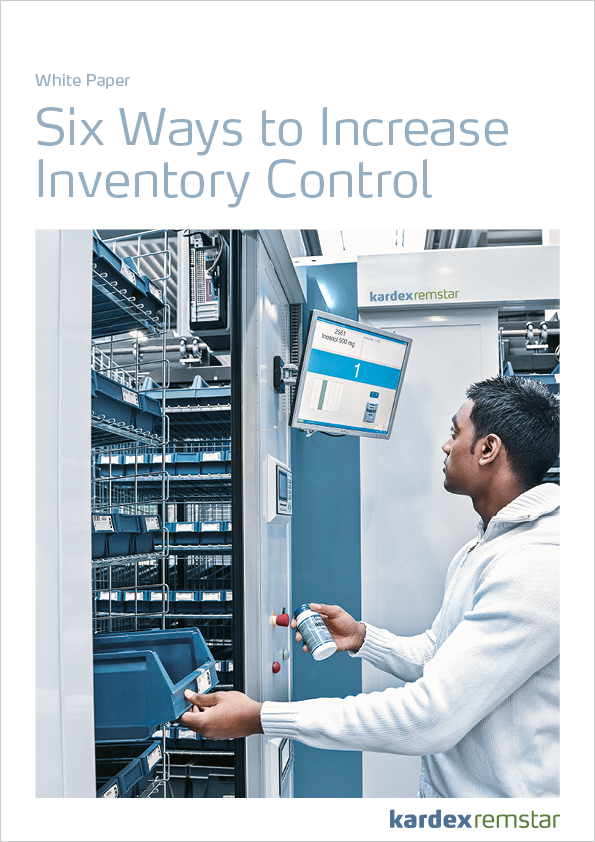

- improve stock and picking accuracy

- save up to 90% warehouse space

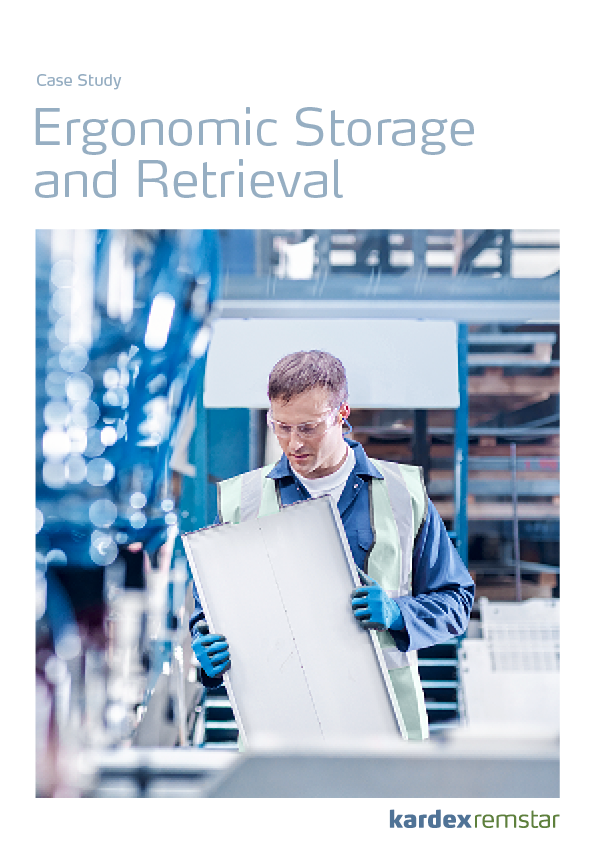

- enable ergonomic working conditions for your warehouse staff

Future warehouses: trends & solutions

As companies gradually make the transition to warehouse automation, they’re able to minimize costs, reduce needed space, and successfully manage fluctuating market demands. Kardex is always up to speed with these latest developments and provides the most up to date tools and technology to support warehouses today and well into the future. Explore some of our industry guides below.

Manufacturing challenges & best practices

For manufacturing warehouses to be successful, operators must maintain accurate control over their inventory, avoid bottlenecks, and be able to deliver goods just-in-time with speed and precision. It is critical to partner with an intralogistics expert who not only understands these complex challenges, but also has vast experience managing them.

Manufacturing case studies

When existing processes are no longer successful, perhaps due to capacity limitations, a spike in demand, additional inventory, or new market requirements, a company must decide how to proceed. Is it time to automate? Is it time to implement new solutions? Dive inside manufacturing warehouses to see how Kardex takes their intralogistics to the next level.

Rubix supports the manufacturing industry by distributing key parts for their production lines. Faced with the daunting task of safely storing hazardous materials like flammable liquids, Rubix needed a new solution that adhered to strict regulatory standards. Watch the video to learn more!

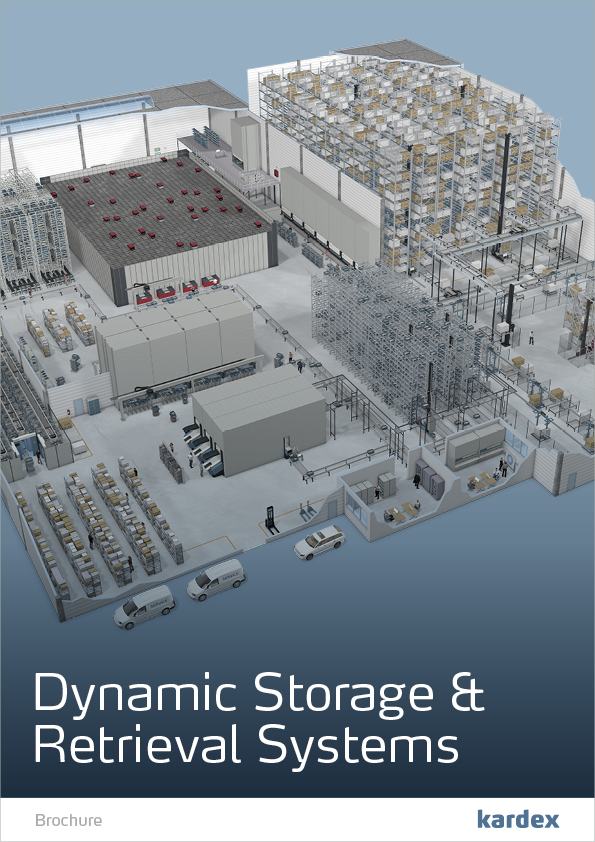

Manufacturing solutions

Warehouses need to implement solutions that meet both today’s needs and can manage future changes and growth. By comparing product specifications and introducing ways to tackle common warehouse challenges, Kardex introduces the latest solutions available and helps evaluate which is best for your industry segment.

Support & Life Cycle Service

Kardex understands how much warehouses depend on fast and reliable maintenance. That’s why our technicians undergo regular training at the Kardex Academy and we offer multiple, modular service contract options. The Kardex team works hard to avoid unnecessary downtime, and ensure systems reach maximum potential throughout their entire life cycle. Read our guides below to see why Kardex should be your ASRS partner.