Faster and error-free order picking

Visual guidance for operators enables faster and error-free order picking

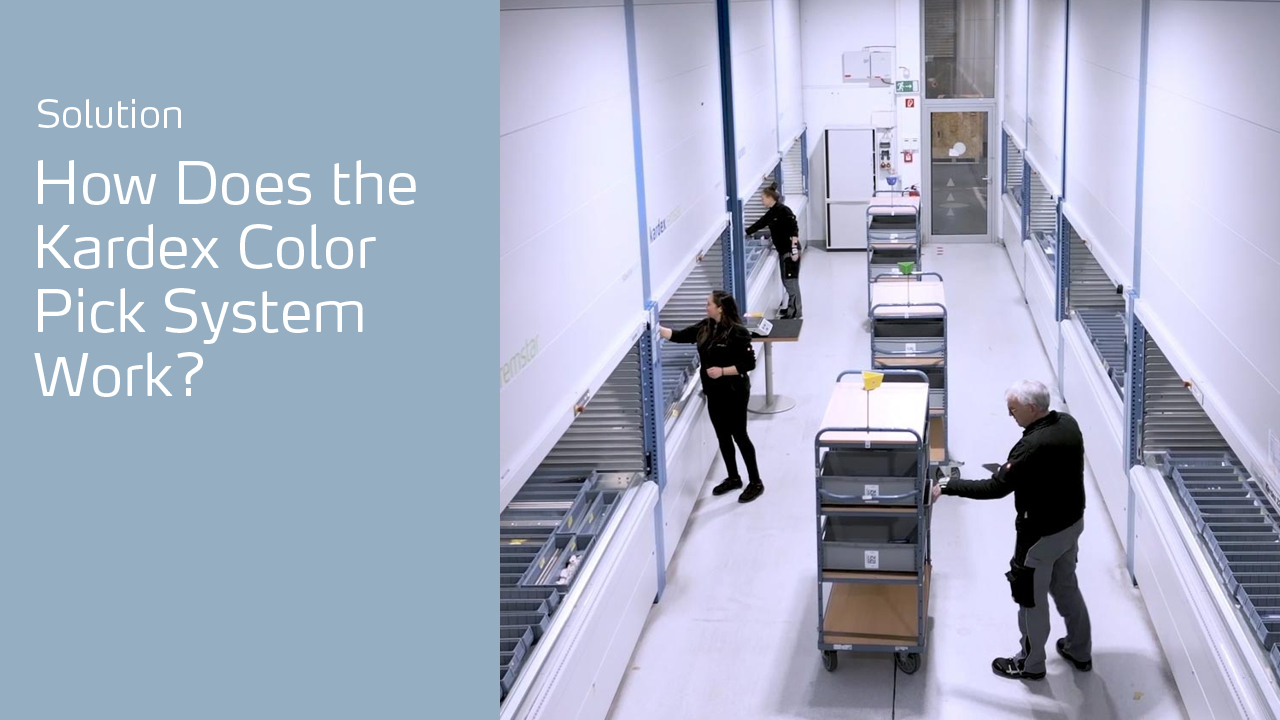

Streamline batch picking, reduce errors, and scale with ease using Kardex Color Pick. A fast, flexible solution for fluctuating order volumes.

What is Kardex Color Pick?

Kardex Color Pick is a dynamic color-guided picking system that shows your team exactly what to pick, when, and where. Using intuitive color-coded carts, bin compartments, and displays, it transforms complex batch picking into simple, visual workflows that anyone can follow.

The result?

- Faster fulfillment

- Error-free order picking

- Flexibility in workforce

Find out if Kardex Color Pick is right for you.

Let's explore how Kardex Color Pick could work for your specific situation in a brief conversation.

Who benefits most from Color Pick?

This solution is designed for operations facing common fulfillment challenges:

-

Fluctuating order volumes that strain your current processes

-

High SKU counts or complex product mixes

-

Tight delivery windows with little room for error

-

Labor constraints or frequent staff turnover

- Orders that require double confirmation

Whether you're managing e-commerce fulfillment, 3PL operations, pharmaceutical distribution, or production facilities, Color Pick adapts to your specific operational requirements.

How e-commerce company Olsson Parts tripled its order capacity with Color Pick

What makes Kardex Color Pick different?

-

Visual simplicity

Your team follows colors, not complex instructions. Each display shows exactly what to pick for which cart and compartment. Eliminating guesswork and reducing training time.

-

Flexible workforce management

Add or reassign operators instantly based on demand. Multiple people can work the same batch without conflicts or bottlenecks, giving you unprecedented staffing flexibility.

-

Faster picking

Batch picking with dynamic zones enables up to 300 lines per hour per operator and reduces walking time.

-

Rapid onboarding

New team members become productive within hours, not days. The visual system is so intuitive that temporary staff can contribute meaningfully from their first shift.

-

Smart Investment

Start with what you need and expand as you grow. All our systems and software are scalable by design.

-

Error-free order picking

With this system you can achieve up to 99.9% in picking accuracy. This reduces picking errors significantly.

Visual simplicity

Your team follows colors, not complex instructions. Each display shows exactly what to pick for which cart and compartment. Eliminating guesswork and reducing training time.

Flexible workforce management

Add or reassign operators instantly based on demand. Multiple people can work the same batch without conflicts or bottlenecks, giving you unprecedented staffing flexibility.

Faster picking

Batch picking with dynamic zones enables up to 300 lines per hour per operator and reduces walking time.

Rapid onboarding

New team members become productive within hours, not days. The visual system is so intuitive that temporary staff can contribute meaningfully from their first shift.

Smart Investment

Start with what you need and expand as you grow. All our systems and software are scalable by design.

Error-free order picking

With this system you can achieve up to 99.9% in picking accuracy. This reduces picking errors significantly.

“By implementing Kardex Shuttles with Color Pick we saved space, got complete control over our inventory, and increased our picking speed.”

Enhanced Precision with the Wearable Task Assistant (WTA)

Take Color Pick to the next level with the Wearable Task Assistant (WTA) - a smart, hands-free device that provides step-by-step instructions directly to your operators. WTA adds real-time confirmation and precision, especially during complex batch picking.Together with Color Pick, they create a seamless, high-accuracy workflow:

- Double verification for critical orders

- Less cognitive load for operators: no second-guessing

- Higher throughput with fewer errors, even during peak periods

This combination is ideal for operations that demand both speed and precision, such as e-commerce fulfillment or pharmaceutical environments.

Common questions

Color Pick uses color-coded visual guidance to simplify batch picking. Operators follow colors instead of printed lists or screens, reducing errors and training time.

Color Pick is most effective in environments with 4–6 machines or more and a high number of SKUs. It’s designed to scale with your business.

Yes. Kardex systems, including those using Color Pick, can be configured to support FIFO strategies. This ensures that older stock is picked first, which is especially important for products with expiration dates or strict inventory rotation requirements.

Yes. Color Pick works as a standalone system. However, combining it with WTA adds step-by-step confirmation and is ideal for high-accuracy environments or complex batch picking.

Multiple operators can work on the same trolley simultaneously, thanks to the system’s flexible and non-linear workflow.

Minimal. Most operators can be trained within hours thanks to the intuitive, visual interface.

Yes. Color Pick is designed to integrate seamlessly with Kardex VLMs, VCMs, and VBMs.

E-commerce, 3PL, electronics and production environments with high SKU counts and fluctuating order volumes or pharmacy companies that require double confirmation.

It allows you to scale your workforce dynamically, reduce walking time, and maintain accuracy even under pressure.

Could Color Pick work for your operation?

You might find this solution particularly valuable if you're responsible for warehouse operations and managing complex order flows, working within tight delivery timelines, or experiencing frequent volume fluctuations that challenge your current processes. Contact us today for an initial consultation.