Automated Warehouse Robots

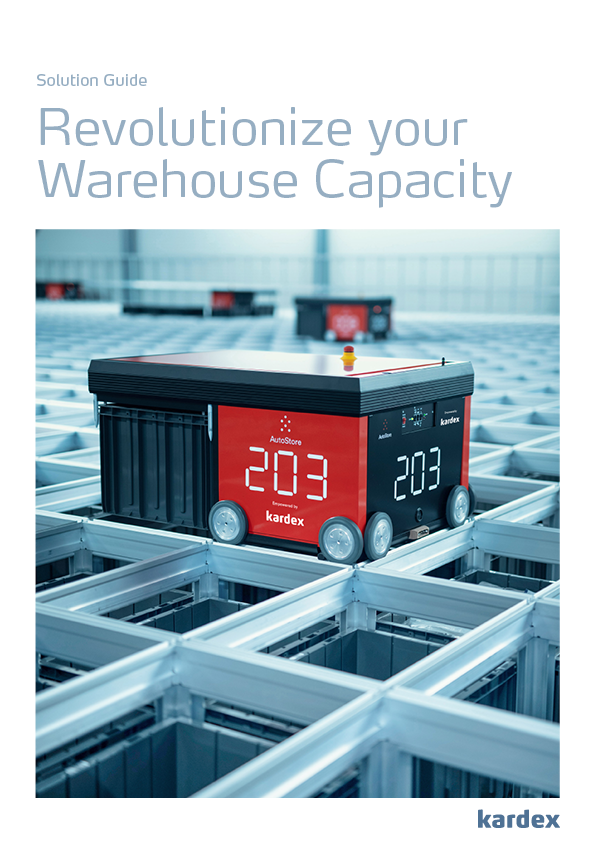

Unlock your fulfillment potential with AutoStore solutions from Kardex

Booming e-commerce business combined with current trends and everyday challenges such as seasonal peaks, changing customer expectations, labor shortage, same-day delivery and buy online – pick up in store (BOPIS) require dependable and flexible warehouse solutions. Companies must integrate new, innovative order fulfillment technologies to stay one step ahead of the competition by meeting today’s requirements and preparing for future changes and growth.

As a global AutoStore partner, Kardex offers the right solution with the fastest order fulfillment system per square meter on the market. AutoStore™ combines the highest storage density of any order fulfillment system with high-throughput technology. The flexible storage and retrieval system uses autonomous robots to process small parts orders quickly and efficiently, performing 10 times faster than manual storage systems. AutoStore solutions from Kardex can be used across all industries and are redefining warehouse operations.

Why AutoStore?

-

Flexible & adaptable

AutoStore can be formed in any shape and around existing columns or other obstacles. The modular system can be expanded without disrupting ongoing operations.

-

Space-efficient

With the best storage density ratio of any goods-to-person system, AutoStore offers four times the capacity with the same floor space compared to manual storage.

-

Reliable

Designed for 24/7 operations, AutoStore offers maximum reliability with an average availability of 99.6%. The system's unique redundancy allows no single point of failure.

Flexible & adaptable

AutoStore can be formed in any shape and around existing columns or other obstacles. The modular system can be expanded without disrupting ongoing operations.

Space-efficient

With the best storage density ratio of any goods-to-person system, AutoStore offers four times the capacity with the same floor space compared to manual storage.

Reliable

Designed for 24/7 operations, AutoStore offers maximum reliability with an average availability of 99.6%. The system's unique redundancy allows no single point of failure.

How does it work?

AutoStore is comprised of one system with five components. Acting as a foundation, an aluminum grid holds durable, stackable bins and creates a track for high-speed robots. The robots move along the top of the grid delivering bins to respective workstations, which are called ports. Here operators will pick or replenish inventory before the robots deliver the bins back into the grid. Users easily control the flexible, modular system by adding and removing robots and ports based on fluctuating throughput demands. See for yourself!

Why partner with Kardex?

-

Experienced team

Kardex has a dedicated team with many years of experience in planning and implementing tailor-made AutoStore solutions within a wide range of industries.

-

Global footprint

Using our extensive nationwide service and support network, you will be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

-

Complete integrated solutions

Our aim is to take everything into account – combining different technologies and providing complete, integrated, and cutting-edge intralogistics solutions from a single source.

Experienced team

Kardex has a dedicated team with many years of experience in planning and implementing tailor-made AutoStore solutions within a wide range of industries.

Global footprint

Using our extensive nationwide service and support network, you will be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

Complete integrated solutions

Our aim is to take everything into account – combining different technologies and providing complete, integrated, and cutting-edge intralogistics solutions from a single source.

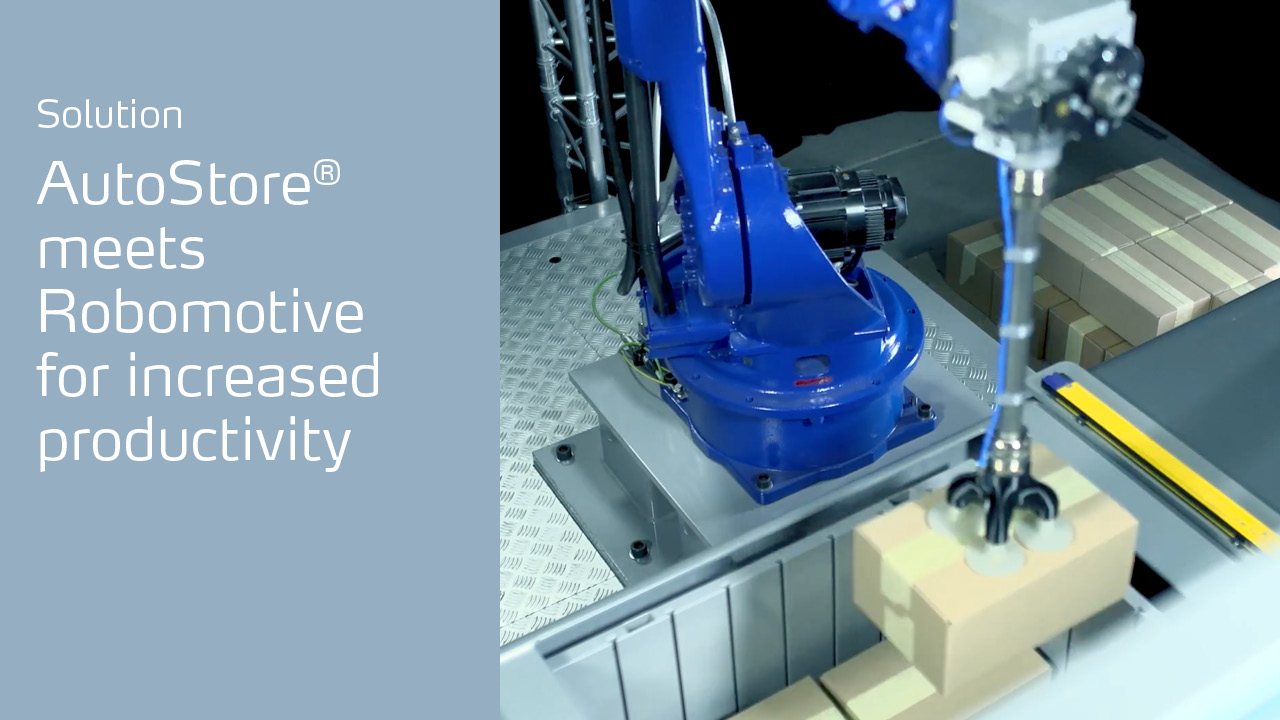

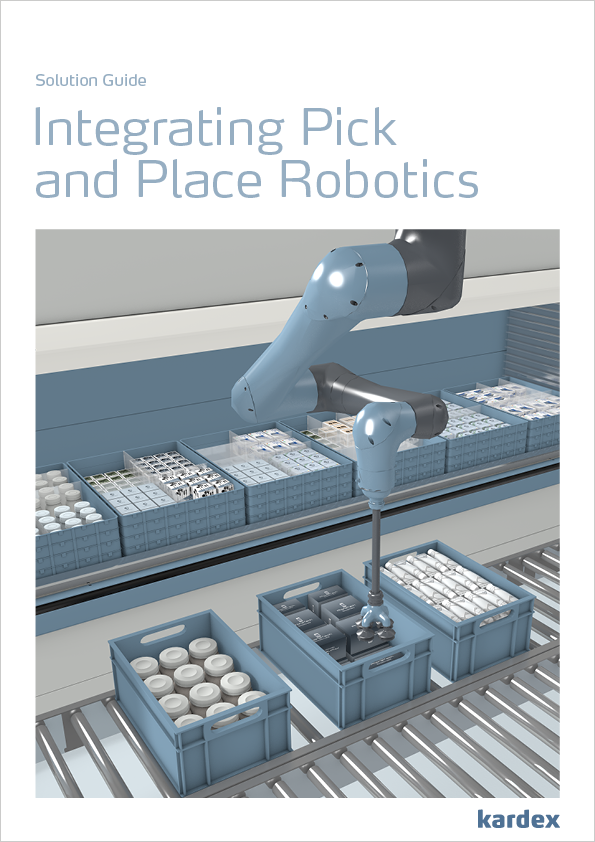

AutoStore combined with Pick and Place Robotics

In cooperation with experts in Pick and Place Robotics, such as Robomotive, Kardex offers fully integrated, complete solutions including robotics from a single source. Pick and place robots can be easily integrated into your future or existing AutoStore system, enabling previously unimaginable performance. Using hardware-independent 3D vision software, pick and place robots can replicate the exact precision and synchronization of a human's eye-hand coordination to create a multifunctional and versatile robotic solution. Typical applications range from fully automated picking and pick & pack solutions to (de)palletizing and replenishment. Using a portal solution, one robot can even serve several AutoStore ports simultaneously, 24 hours a day at high speed.

Your benefits at a glance

-

Increased picking performance and quality

-

Working flawlessly 24/7

-

Reduced operating costs

Increased picking performance and quality

Working flawlessly 24/7

Reduced operating costs