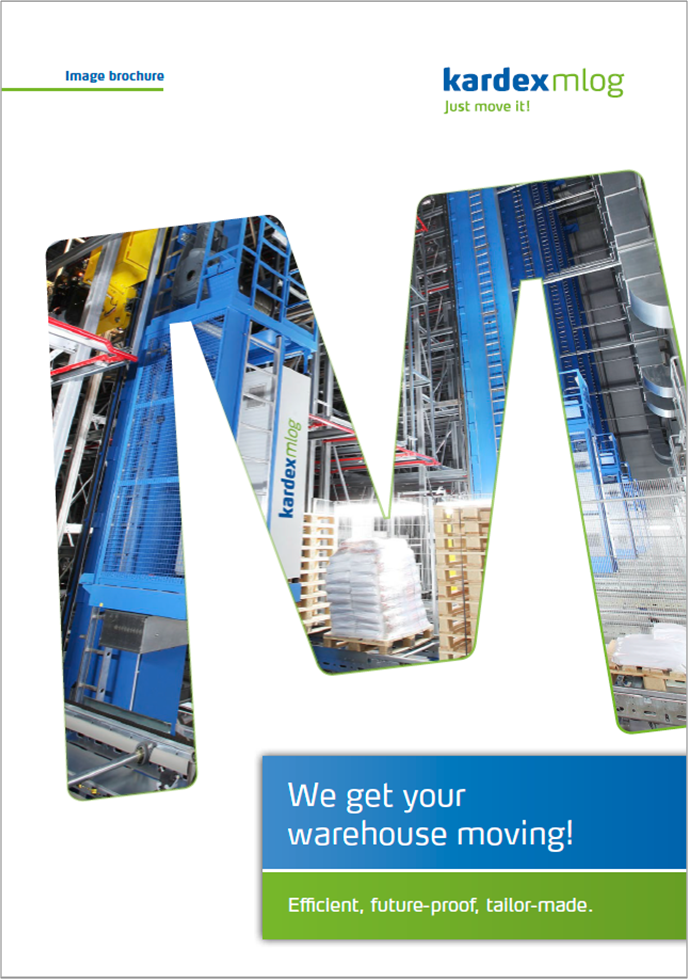

Automated warehouse Using standardized components to create a customized AS/RS

Each industry has its own specific requirements – and so does each company and with that each warehouse. With our tailored concepts, we ensure that all your processes are optimally coordinated and that, from day one, your plant can be operated with the performance and capacity to perfectly fit your operations.

-

Optimize your processes

-

Maximize your warehouse capacity

-

Increase your productivity

Optimize your processes

Maximize your warehouse capacity

Increase your productivity

The right solution for each requirement

The performance and efficiency of your plant depend on making the right decision for your warehousing solution. The following factors are vital in this decision:

- Warehouse capacity

- Number of different articles

- Dimensions and weight of the articles to be stored

- Frequency of access

- Building dimensions

- Material flow and processes

- Level of automation

The options and solutions for storage and staging of your goods are many and varied. For this reason, we focus on an individual analysis of the requirements and on consultation to jointly identify the best solution.

From pallets, to containers, right up to industry-specific solutions

Tab Navigation

High-bay warehouse for pallets

With heights of up to 45 meters and options for single-deep or multiple-deep storage, Kardex high-bay warehouses offer maximum flexibility and optimal use of available space.

Automated miniload system for small parts

With heights of up to 24 meters, different load handling devices, and options for single-deep or multiple-deep storage, our automatic small parts storage solutions are suitable for all requirements.

Storage without load carriers

Automated storage of goods without load carriers can reduce the number of handling steps in storage and retrieval and also in picking, and makes your system more dynamic.

Is your warehouse due for an upgrade?

With our comprehensive refurbishment portfolio, we have just the right solution for you:

- Reorganization & optimization of processes

- Plant extension

- Automation of manual storage areas

- Replacement of individual components or complete units

- Upgrade and replacement of IT systems

- Implementation of safety and energy efficiency concepts

Advantages of a Kardex automated warehouse

-

Tailored solution

-

High storage density

-

Optimal usage of space

-

High process reliability and speed

-

Maximum availability and efficiency

-

Verifiable controlled conditions

Tailored solution

High storage density

Optimal usage of space

High process reliability and speed

Maximum availability and efficiency

Verifiable controlled conditions

Discover our extensive portfolio:

- Automated storage solutions

- Software integration

- Life Cycle Services

- Best Practices

Relevant elements for automated storage systems

Tab Navigation

Conveying systems

The wide range of standardized conveying technology elements and our experience in complex material flow systems enable us to develop high-performance and reliable solutions.

Stacker cranes

The modular stacker cranes for automated storage of pallets, wire mesh containers and small parts are highly versatile and offer numerous configuration options.

Software solutions

Kardex develops modular IT concepts that can be tailored to the specific intralogistics processes and requirements of your warehouse, and that coordinate and monitor these processes over the long term.