Frequently Asked Questions

FAQs: AutoStore empowered by Kardex

What is AutoStore?

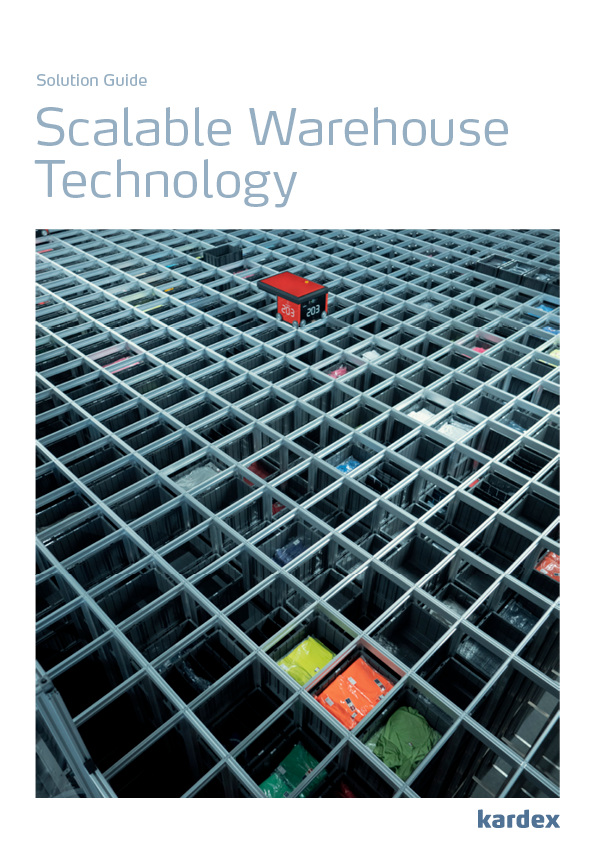

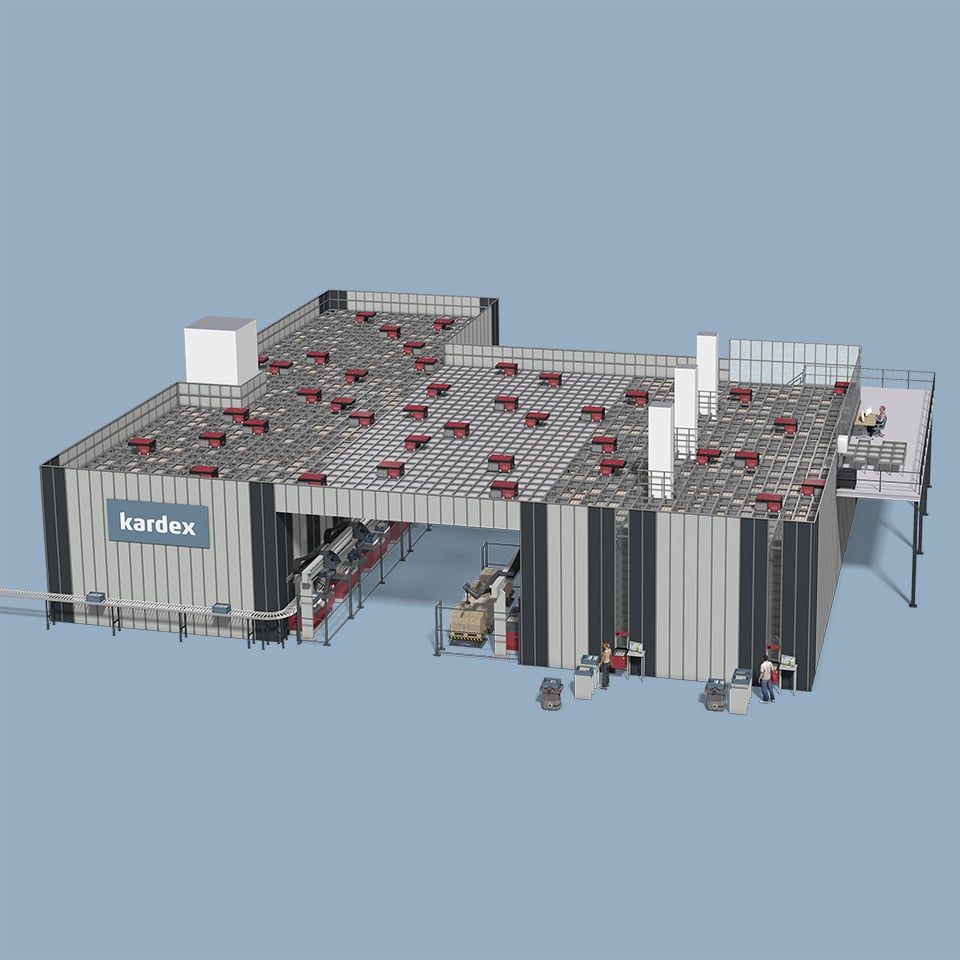

AutoStore is an automated storage and retrieval system, or AS/RS, also known as Cube-Based storage due to its shape and density. The design of AutoStore removes all excess space and air normally found around items traditionally stored on shelves.

Consisting of only 5 modules, items are stored in Bins which are stacked next to and on top of each other like building blocks within an aluminum Grid. Robots drive on tracks along the top continuously digging, retrieving, and delivering Bins to Ports (workstations) as directed by the system. Human workers access the inventory at the Port for order fulfillment. Robots then collect the Bins back to return to the Grid.

The result is a warehouse automation system providing brands with the reliability they need to create customer-winning logistics through speed, accuracy, and efficiency.

What is the operational temperature for the AutoStore modules?

Most AutoStore modules are approved for a temperature range of 2-35 degrees Celsius (35.6-95 degrees Fahrenheit). The individual module operating temperature range information can be found in its product page technical specification section.

Can we use our existing software (ERP/Warehouse) with AutoStore?

Yes, probably. AutoStore offers different standard interfaces (APIs) for the communication between AutoStore and WMS (picking, goods in, and Port operations).

Are the Ports secured regarding injuries? What happens if someone puts a hand in the Port while Bins are exchanging?

All AutoStore Ports are equipped with multiple technical safety measures. Incorporation of safety measures; such as emergency stop button, guards, and safety hatch (measures may vary depending on the Port);ensures secure operation and prevents the possibility of crushing injuries. If someone puts a hand in the Port while Bins are exchanging, it will trigger the safety stop, and the Port will cease all movement immediately and activate the emergency stop to assure Port remains safe to use. For the Port implemented with a safety hatch, the hatch will only open once a Bin is ready for a pick to guarantee safe operation.

What is the man hour efficiency improvement I can expect using the AutoStore?

This is case-by-case since there are many factors influencing this calculation (e.g. picking speed before and after, error reduction ratio, or storage area reduction).

Is it possible to install AutoStore if the height of the Grid will not be the same all over the Grid (different height from the top of the Grid to the floor)?

Yes, our only requirement is that the top of (each) Grid is flat (on the same height level).

Do I need to remove existing pillars in my warehouse to install AutoStore?

No, AutoStore can be designed around obstacles like pillars, pipes, and walls.

Is it possible to use AutoStore for deep freeze warehouses?

No, it is not approved by AutoStore to have an AutoStore system in an environments less than 2 degrees Celsius (35 degrees Fahrenheit).

Is it possible to use AutoStore for cold/refrigerate warehouses?

Yes, it is possible to use AutoStore modules in a refrigerated warehouse down to 2 degrees Celsius (35 degrees Fahrenheit) provided it is a constant environment (e.g. low, constant humidity and temperature; Operating humidity on the modules is 40-90%, non-condensing).

Can AutoStore be used in a clean room environment?

The modules only have IP20 and are not approved for a clean room environment.

What is the mean time between failures (MTBF)?

Mean time between failures (MTBF) is the average time between system failures and is used as a system reliability parameter. Our system MTBF is calculated by dividing the total number of hours our Robots are running by the total number of system failures. An accurate measurement of MTBF is highly dependent on the shift duration, temperature, average Bin load, and other circumstances, but our customers have achieved an MTBF of over 3,000 hours. AutoStore continuously aims to improve system performance and continues searching for new ways to increase uptime for our customers.

What is the power consumption of AutoStore?

Best in class. One comparison done by a customer shows AutoStore use 10-15% of energy when compared with mini-load. A system with 10 Robots needs the same amount of energy as a vacuum cleaner.

Is it possible to change the picking list?

Yes, changes of already transferred tasks or task groups to AutoStore are possible. But each change may have a negative influence on the speed and efficiency of the system later on as the system may already have used Robot resources to prepare that Bin.

How much time does it takes to pick up a Bin stored at the bottom of the Grid?

For an example of an installation of 16 Bin levels: Minimum of 3 minutes, 36 seconds (plus 3 minutes, 36 seconds to cleanup afterwards).

But this digging process will normally be done in the background and in advance (i.e. before the Bin is requested and presented at a Port).

Does the system need to shut down if a Robot jams on the Grid?

No. The AutoStore software module, XHandler, will attempt to resolve error situations that occur with the Robot without stopping the system. If the issue cannot be resolved through automation, the control software can temporarily isolate the affected area while keeping the system running and only halt the system as a last resort.

In which project situations is AutoStore particularly advantageous?

- Brownfield locations and/or space constraints

- High number of Bins needed

- Project with significant security concerns

- High-visibility locations

- Fast-growing business

- Time constraint projects

- Workstations with throughput needs of up to 650 bins per hour

What makes brownfield locations, or other locations with space constraints, particularly suitable for AutoStore?

AutoStore can leverage space more efficiently in a brownfield location, or other locations where space is limited, due to its dense design. Because AutoStore condenses the space between items through utilization of a cube design, it provides a solution that automatically reduces a storage footprint by up to 75%. This provides options for operations wishing to stay in their current location or move to a building closer to their customers (final mile delivery).

What makes a high number of Bins particularly suitable for AutoStore?

The cube storage grid design with flexible robots (which are not limited to specific parts of the grid) enable a high efficiency even for projects with a high number of Bins.

What makes projects with significant security concerns particularly suitable for AutoStore?

AutoStore solutions are theft-proof due to its cube storage design; only the very top layer is accessible by humans, but even this would require significant effort and can be monitored by camera. In addition, bins are not see-through and compactly stored within the grid. Only the system has a record of what item is in what Bin and this is traceable through an audit trail which records all Bin movement.

What makes high-visibility locations particularly suitable for AutoStore?

The AutoStore solution is sleek and elegant. Our Robots are quiet workers with R5 running at only 70db and B1 even lower than that. This makes it suitable for in-store or library applications.

What makes time constraint projects particularly suitable for AutoStore?

AutoStore is easy to implement with an average installation time of just 20-26 weeks, about 50% lower than most aisle-based solutions.

What makes fast-growing businesses particularly suitable for AutoStore?

AutoStore is future-proof and its grow-while-running ability makes it particularly suitable for high growth companies like e-commerce players ramping up capacity by an order of magnitude. Expanding AutoStore can happen in various ways from adding more Robots, Ports, and/or Bins for capacity and higher throughput, to expansion of the Grid for additional storage space. All can happen without interrupting ongoing warehouse operations and maintaining the same reliability (uptime), performance, stability, and usability our customers have come to expect from AutoStore. Some of our customers are on their eighth system expansion.

Is it possible to relocate the AutoStore system?

Yes. The AutoStore system, including the existing modules, can be relocated without any major disruptions.

It is important to note that all components must meet the quality requirements of the AutoStore to be reused.

Are certain industries more suitable for Black Line vs Red Line solutions?

No. Black Line and Red Line address different throughput requirements, which can vary even within one industry.

What are the typical recharging cycle time of R5 and R5+ Robots (example: minutes to recharge per hour of operation or describing a shift operation)?

A typical working day for R5 and R5+ is about 20 hours. Each Robot needs at least 4 hours of charging per day. Robots will charge whenever they see an opportunity to do so (during breaks or low-capacity periods). The AutoStore Red Line can and does support 24-hour operations. We are happy to discuss how to make this happen and invite you to contact our team for more specifics.

Are there any limits to the size of the Grid?

Max height is 16 of the 330 mm Bins or 24 of the 220 mm Bins resulting in 5.4 m (17.75 feet). With Robots and recommended service space, the height is 7.52 m (24.67 feet) in total.

The max height for the 425 mm Bins is 14 high of the 425 mm resulting in 6 m (19.6 feet). With Robots and recommended service space, the height is 8.18 m (26.84 feet) in total.

What is the minimum height required for the Grid?

This depends on the design. At the very least, the minimum height must be as the following plus the Grid track above it:

- 220 mm Bin: 6 Bins

- 330 mm Bin: 4 Bins

- 425 mm Bin: 3 Bins

This Bin depth provides the needed height for a Port.

Less space is needed if the track is used "only" as a road for transporting Bins between different Grids. In this case, the design can either be a track with no Bins or a track with at least one Bin plus the track above.

How much space do we need between the roof and the top of the Grid?

For Robot trafficking we need 600 mm (2 feet) for R5 and 860 mm (2.8 feet) for B1.

It needs to be possible for service and support staff to operate and use the AutoStore service vehicle on the grid. The recommendation from AutoStore is at least 2 m (6.5 feet) of open space above the Grid. In special cases a lower height could be accepted by the local authorities, but this needs to be clarified and approved by the local authorities and the local AutoStore distributor.

Is it possible to have AutoStore Grids installed on different floor levels in the building?

Yes. Bin Lift Grid-to-Grid (G2G) configuration allows Bins to flow between Grids on different floor levels.

Bin Lift is currently only available in the EU, United States, Canada, Japan, Korea, China, Israel, Panama, Serbia, and Uruguay.

We are working on adding more countries with the applicable product approvals. Note that it may take longer in some countries to get approval.

Is it possible to clean the Grid?

Yes. AutoStore Track Cleaner, a Bin equipped with a vacuum cleaner brush, helps clean the Grid both during and after operations by removing dust, dirt, and grime buildup from the Grid tracks. An AutoStore Track Cleaner works autonomously, allowing customers to effortlessly maintain cleanliness, avoid unwanted downtime at an inconvenient times, and maximize the system uptime.

What is the weight limit for a Bin?

Maximum load today is 30 kg (66 lbs).

Is it possible to have different AutoStore Bin sizes in one Grid?

No, mixing different Bin sizes is not supported by AutoStore.

However, movable dividers offer the most efficient and flexible solution. They allow customers to easily create various-sized compartments in Bins and fully utilize the maximum internal storage volume.

Is it possible to put different products into one Bin?

Yes. AutoStore™ Bins are also prepared for the usage of physical and adjustable dividers which insert into the Bin to create multiple compartments (up to 32). It is up to the WMS to administrate and maintain the content of the Bins (stock/SKU).

What are the inner dimensions of the Bins?

Approximate inside dimensions:

- 220 mm Bin (Small): 600 x 400 x 200 mm (23.6 x 15.75 x 7.9 in)

- 330 mm Bin (Medium): 600 x 400 x 310 mm (23.6 x 15.75 x 12.2 in)

- 425 mm Bin (Tall): 600 x 400 x 400 mm (23.6 x 15.75 x 15.75 in)

What throughput can we expect from the AutoStore™ Ports?

While an accurate throughput may vary case-by-case due to various factors, the throughput of each Port is as follows:

- ConveyorPort: designed to handle 240 Bins/hour per Port when located on a mezzanine level. When placed at the floor level, the throughput is 180 Bins/hour per Port.

- CarouselPort: designed to handle 400 Bins/hour per Port.

- SwingPort: works with Bin Lift to offer 170 Bins/hour per Port.

- RelayPort: built to handle up to 650 Bins/hour per Port. The modularity of the Port allows you to add from two to six-Tab modules to buffer more Bins inside the Port.

- PickUpPort: designed to handle up to 170 Bins/hour per Port at full height Grid (6 meters) with 5 seconds handling time. Maximum Bin throughput is subject to change depending on the height of the Grid.

- FusionPort: built to handle up to 550 Bins/hr./Port.

- FusionPort Staging: Up to 550 Bins/hr./Port for source Bin openings and 400 Bins/hr./Port for target Bin openings.

A simulation of the AutoStore design will provide the most accurate scope of the Port throughput.

What is the Bin Lift and how does it work?

The Bin Lift is a vertical lift for AutoStore Bins.

With the Bin Lift, the customer can either place the Port and operator on a different floor level than the Grid (G2P), or connect Grids located on two different floors (G2G). This lets customers optimize the use of different floor level spaces efficiently and extend Bin reachability.

G2P: Works in combination with the SwingPort to provide an extension to the Grid. It allows order picking to happen from a different floor than the Grid and enables flexibility in the existing space design.

G2G: Connects two Grids on different floors, enabling the flow of Bins between the Grids. It allows customers with multi-level warehouses to optimize their use of space and extend Bin reachability. The AutoStore Grid-to-Grid Port Manager ensures a smooth transfer of Bins between two separate Grids, however the customer’s warehouse management system (WMS) is responsible for maintaining and balancing Bins between two Grids.

Currently, the Bin Lift 2.0 is available in the EU, United States, Canada, and Japan.

We are working on adding more countries with the applicable product approvals. Note that it may take longer in some countries to get approval.

.png)