Berkshire Grey: Robotic Piece Picking Fully automate your picking tasks from your AutoStore ASRS, enabling 24/7 order fulfillment. Empowered by Kardex—the first to successfully deploy this innovation.

Contact UsProven robotic picking technology purpose-built for AutoStore, supported by Kardex FulfillX Software.

-

Enable same-day shipping

With around-the-clock picking at rates up to 650 picks per hour.

-

Reduce labor dependancy

Labor can be hard to find — robots work 24/7.

-

Optimize throughput of existing facility

Maximize the throughput & efficiency of your existing facility before considering relocation.

Enable same-day shipping

With around-the-clock picking at rates up to 650 picks per hour.

Reduce labor dependancy

Labor can be hard to find — robots work 24/7.

Optimize throughput of existing facility

Maximize the throughput & efficiency of your existing facility before considering relocation.

First real-world implementation ever

Do I need a 3rd-party software to integrate robotic picking with AutoStore?

Not with Kardex. Our in-house software, FulfillX, seamlessly integrates AutoStore with robotic picking—eliminating the need for additional third-party software. Purpose-built for AutoStore, FulfillX is a proven solution that ensures smooth, efficient, and intelligent automation.

How FulfillX powers robotic bin picking

- Location – It determines exactly which bin compartment contains the required item, ensuring the robotic arm picks from the correct position.

- Order – It sequences the picks efficiently, minimizing movement and maximizing throughput.

- Quantity – It dictates the precise number of units to be picked from each bin, ensuring order accuracy and reducing errors.

- Flexibility - adds flexibility to the WMS to drive product sequencing within a container. For example, it ensures heavier products are placed at the bottom to prevent damage to lighter items on top, enhancing both order integrity and packing efficiency.

Demo at the world's first live site

Join us for an exclusive event and experience robotic picking firsthand at the world's first live site. Discover its seamless integration with Kardex FulfillX software, explore the range of items it can pick, and uncover the top use cases for its implementation.

How does it work?

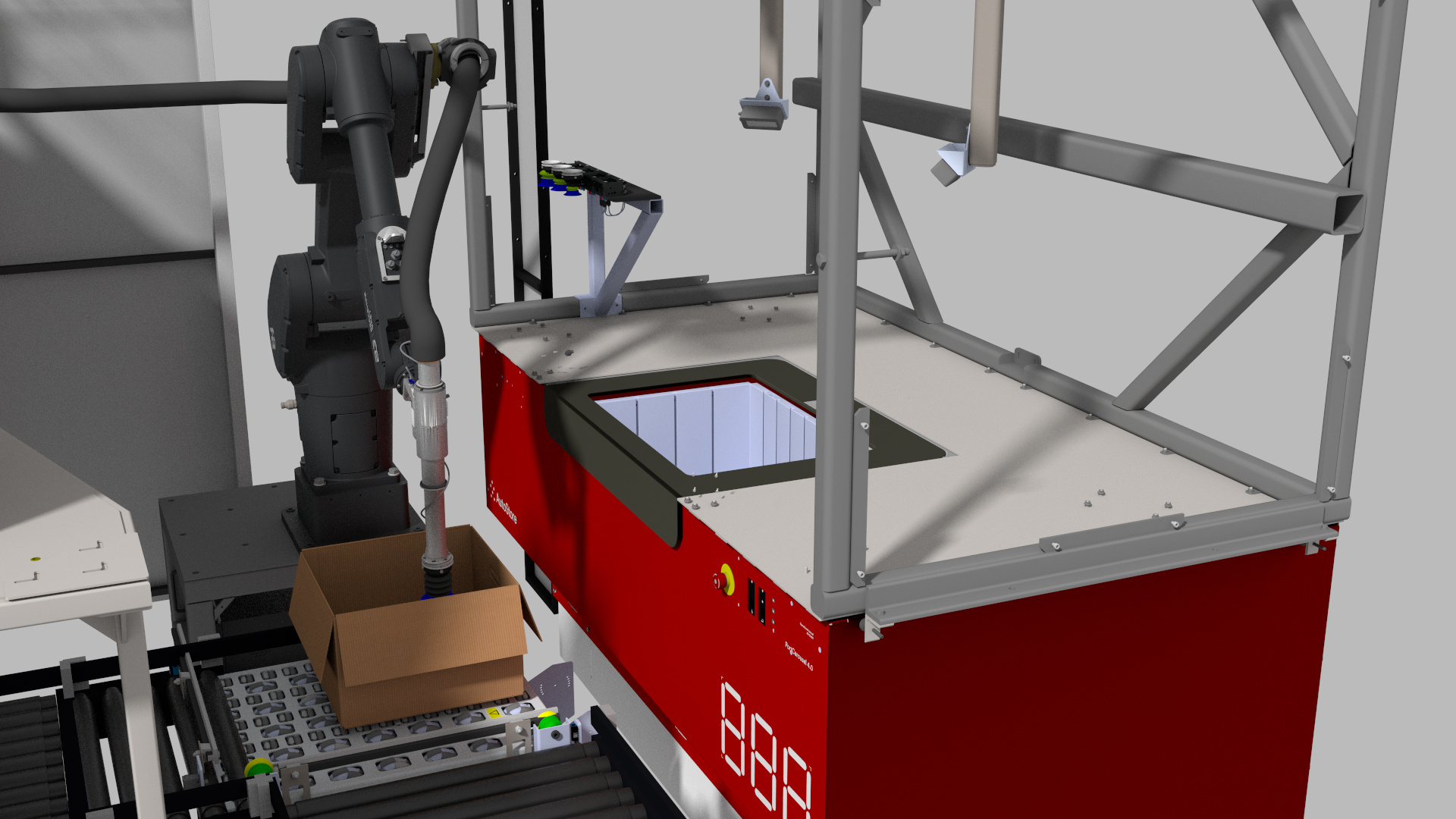

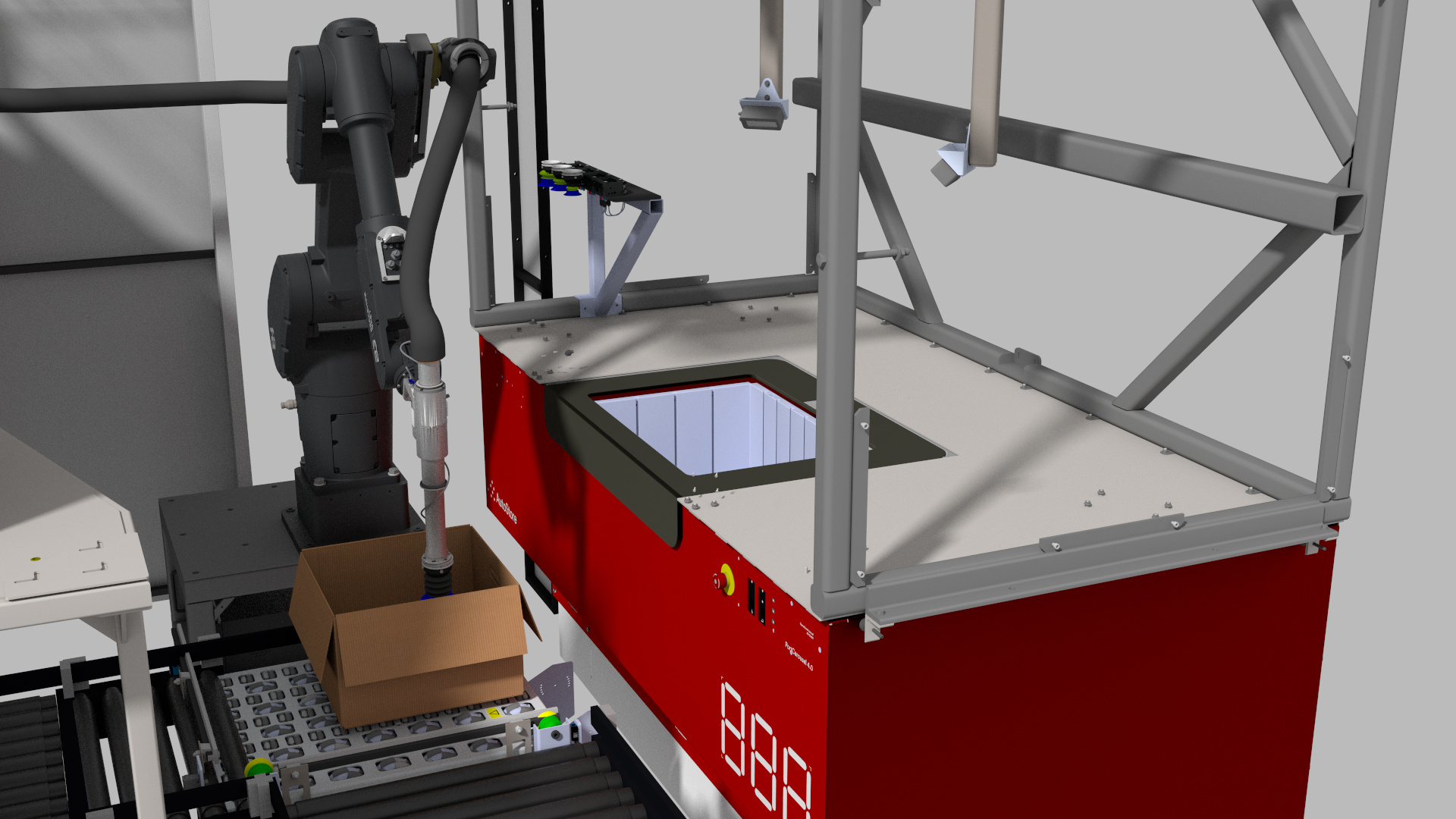

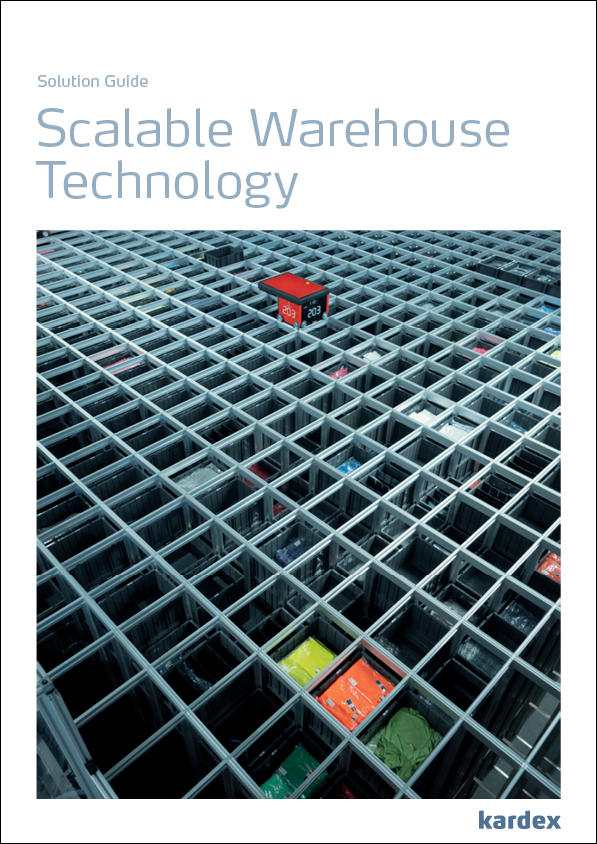

1. Inventory bins delivered to AutoStore port

The AutoStore robots retrieve inventory bins out of the storage grid and deliver them to the CarouselPort.

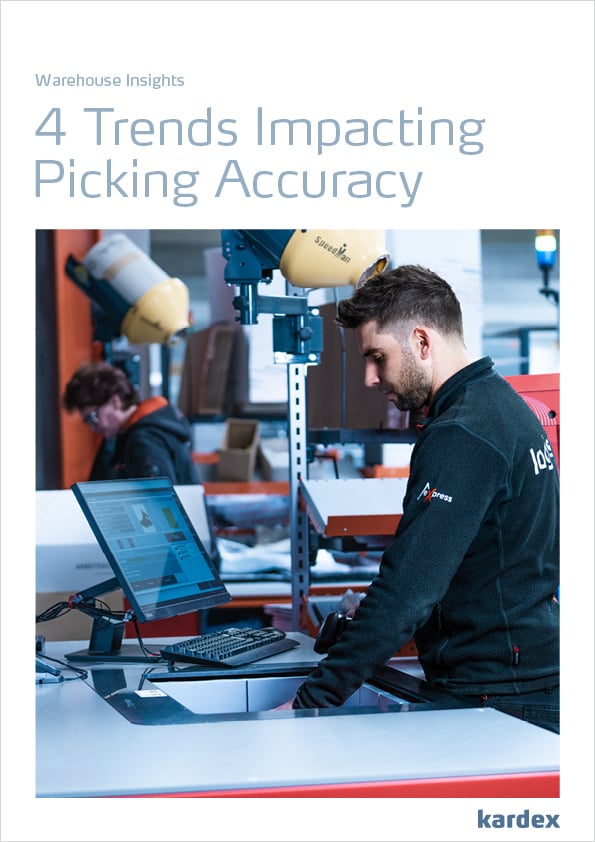

2. Outbound containers arrive to pick cell

An in-feed conveyor transports totes or cartons directly to the picking cell to receive items for outbound shipment.

3. Kardex FulfillX dictates the location, order, and quantity

FuflillX acts as the integration hub between AutoStore and the robotic picking solution, controlling the bin compartment and quantity for each pick. It dictates the location, order, and quantity for the robot to pick, ensuring seamless coordination between AutoStore and the robotic system.

4. Optimal grasp & placement location identified

Perception module identifies optimal grasp point of the item in the inventory bin and the optimal placement position in the outbound tote or container.

5. Item is picked and placed

The robotic arm picks the item from the inventory bin and places it in an outbound container.

Why partner with Kardex for robotic bin picking?

-

Proven performance

No need to wait until Summer 2025—our solution is already picking orders.

-

Seamless integration

Kardex FulfillX ensures real-time coordination between AutoStore and the robotic picking solution.

-

Real-world expertise

We're not just talking about robotic picking—as the most innovative AutoStore partner, we've implemented it, optimized it, and delivered results.

Proven performance

No need to wait until Summer 2025—our solution is already picking orders.

Seamless integration

Kardex FulfillX ensures real-time coordination between AutoStore and the robotic picking solution.

Real-world expertise

We're not just talking about robotic picking—as the most innovative AutoStore partner, we've implemented it, optimized it, and delivered results.

.jpg)