AutoStore Robotic Cube Technology

Calculate Your ROIUnlock your potential with AutoStore robotic cube technology

-

Fastest fulfillment

per square foot

-

Scalable processes

to manage fluctuating demand

-

Expand capacity

up to 400% without moving

Fastest fulfillment

per square foot

Scalable processes

to manage fluctuating demand

Expand capacity

up to 400% without moving

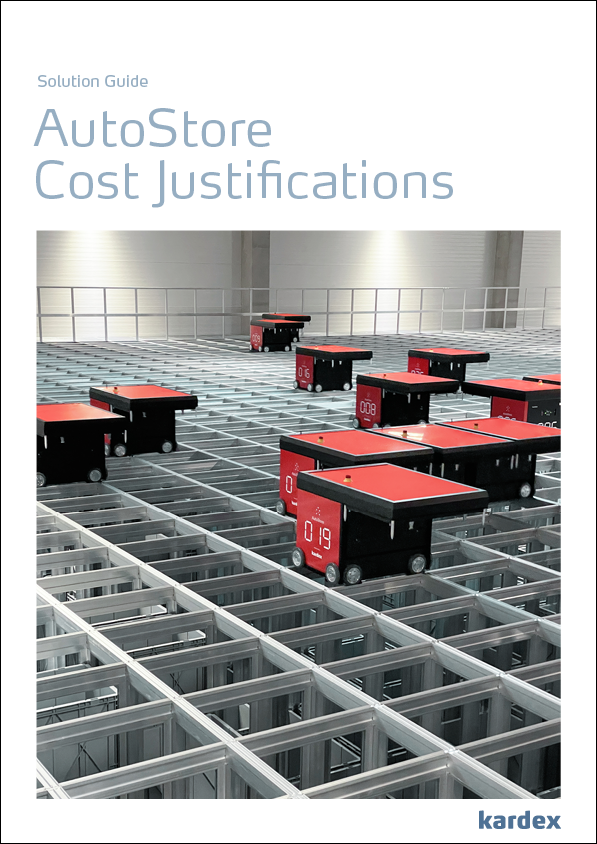

How does AutoStore work?

AutoStore is the fastest order fulfillment system per square foot in the market.

The automated storage and retrieval system is operated by autonomous robots that move on top of an aluminum cubic grid. Within this grid, storage bins are stacked on top of each other. The robots continuously pick up, rearrange and deliver bins directly to connected ports for order picking and replenishment.

Designed to handle any kind of small parts, these high-speed robots are redefining manufacturing, warehousing, retail and distribution operations worldwide.

With a modular design, AutoStore systems can easily be expanded without impacting ongoing operations. The flexible grid system maximizes storage density, enabling the inventory to be quadrupled in the same space compared to conventional systems. With a global average availability of 99.6%, AutoStore is the most efficient and reliable storage system in the world.

Justify your investment in AutoStore

- Improve space utilization

- Smart slotting & storage locations

- Reduce labor costs & related challenges

- Decrease mispicks

- Expand storage capacity 4X

- Support company growth

System components

Tab Navigation

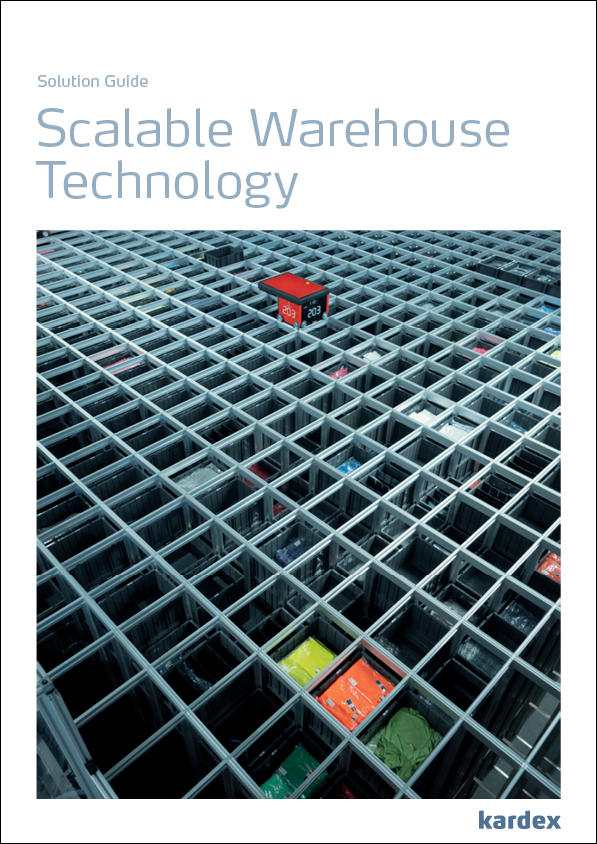

Grid

The modular aluminum grid is lightweight and flexible. It holds the bins stacked neatly while providing tracks for robots to drive on. It can be installed to fit any warehouse size and shape and placed around columns, on mezzanines and on multiple levels - to maximize your existing warehouse space.

Bins

Durable, specialized, and stackable bins hold inventory and the weight of multiple bins stacked one above another. Each bin can hold a single SKU or be subdivided into multiple storage locations. Bins are stacked, sorted, retrieved and delivered to ports by the robots.

All bins can be made of either polyethylene (HDPE) or anti-static ESD and are available in 3 different heights.

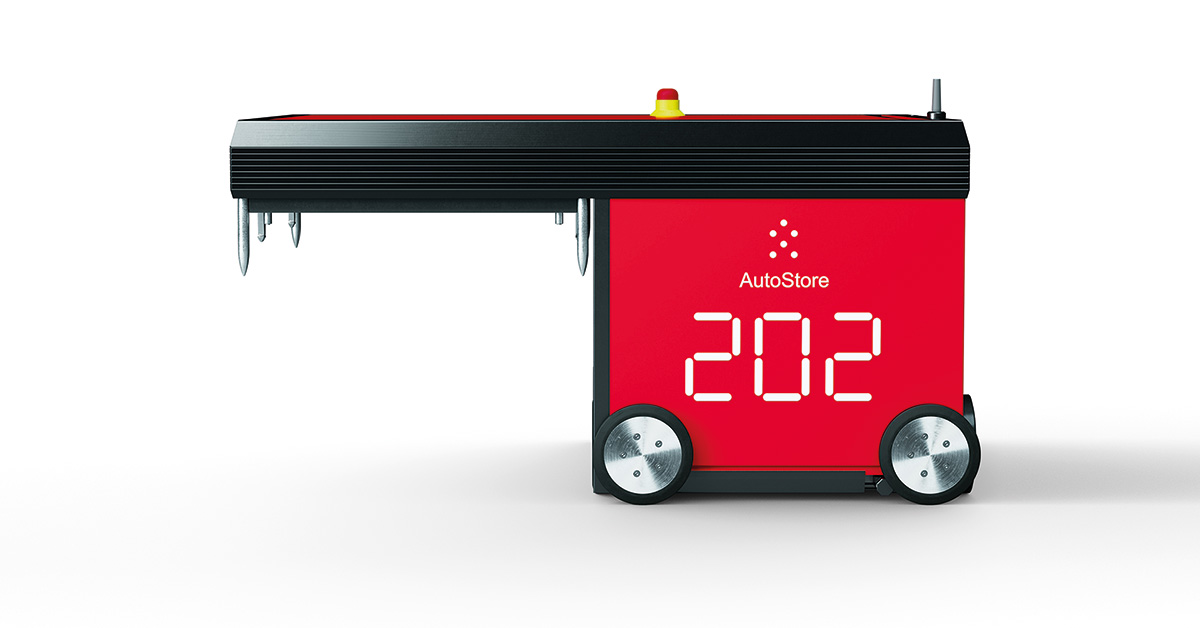

Robots

High-speed robots drive along the top of the grid and retrieve any bin, from top to bottom. They operate around the clock regardless of lighting or heating providing system redundancy as any robot can access any bin. If one robot breaks down, no problem - another one takes over its tasks.

There are multiple types of robots available - all wirelessly connected!

The NEW R5+ robot is built and based on the same iconic R5 technology. Designed with extra capacity, the R5+ handles all three AutoStore Bin sizes, including the tallest 425 mm bin. By making the largest bin compatible with our most popular robot, AutoStore continues to provide the fastest and most reliable order picking solution today.

The R5 Red Line robot is a reliable warehouse worker digging, carrying and delivering bins to ports non stop. The Red Line robots use bin lifts to reach down to retrieve a bin and carry that bin next to the robot. The Red Line docs itself to recharge when not in use. The 220 mm and 330 mm tall bins can be used with the R5 Red Line robot.

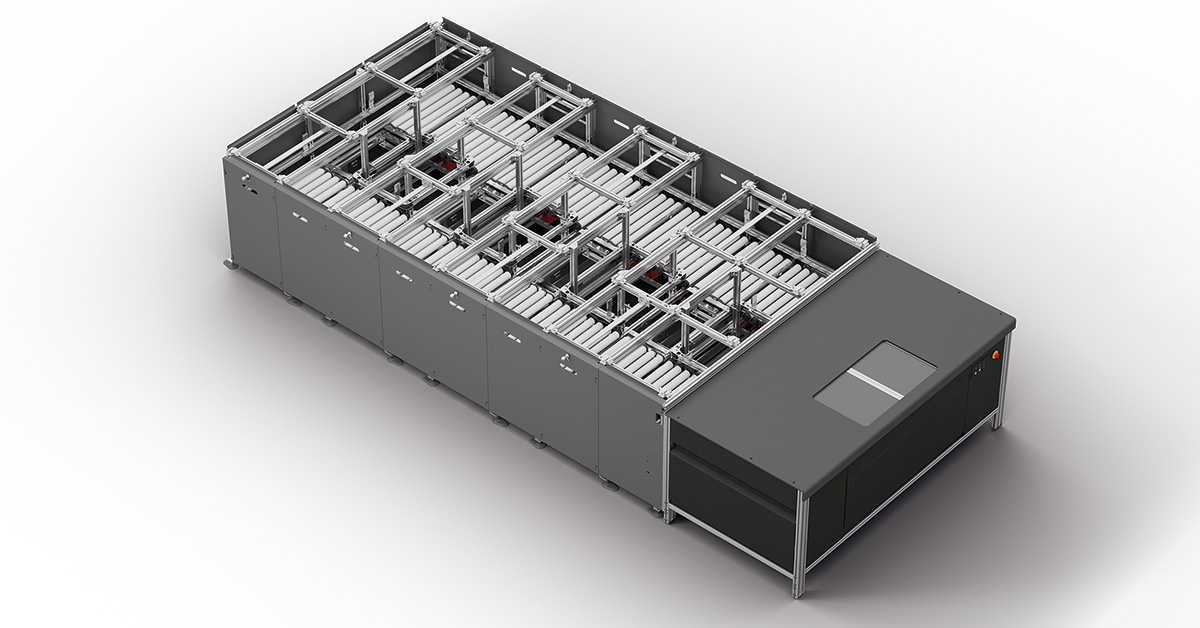

Ports

Ports, or workstations, are where bins are presented for picking, replenishing or other inventory actions. A wide range of ports offering various functions and speeds are available.

Ports can be further enhanced with pick-to-light technology, which is especially helpful when bins are sub-divided for multiple SKUs. A software driven laser pointer will guide the operator to the exact pick location to increase pick accuracy and speed.

There are 4 ports available, ensuring you get the bins when and where you need them.

Conveyor Port: the simplest workstation providing operator access to a presented bin

Carousel Port: the three bin carousel workstation for efficient product flow

Swing Port: the workstation that vertically connects floors allowing the grid to be on one floor and the picking to be on another

Relay Port: the workstation built for speed using a series of conveyors and cross wagons

Controller

The brains of the system - the controller always keeps track of everything. It acts as the command center, traffic control and database holder for the entire AutoStore system.

AutoStore has a standard proven SAP/ERP connection for easy integration with your current processes.

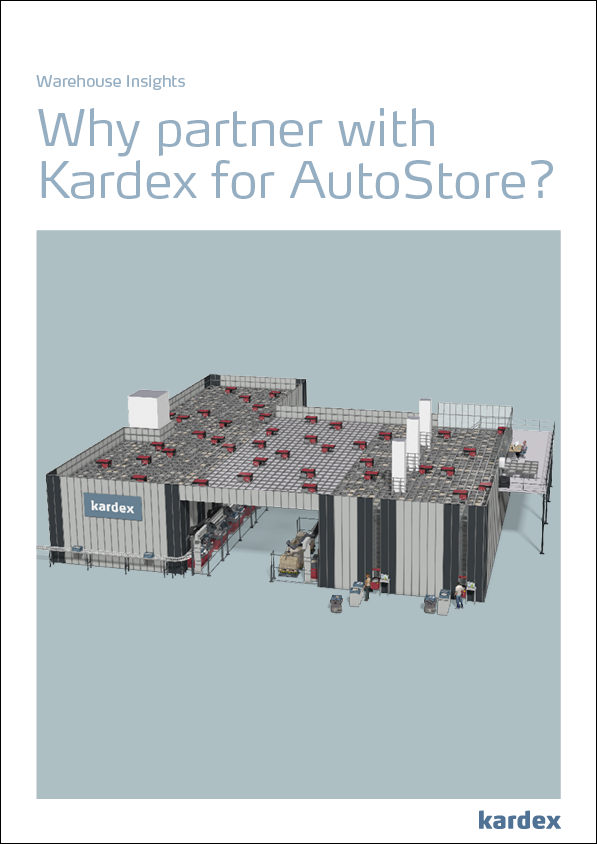

Why partner with Kardex?

-

Dedicated project management

Kardex has dedicated project managers committed to working side by side with you through system concept, design and installation.

-

Guaranteed installation & ramp up support

We don't leave after your AutoStore system goes live. We will be onsite during the installation and ramp up phase to ensure a smooth transition for you and your team.

-

Local ongoing support & maintenance

Using our extensive nationwide service and support network, you'll be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

Dedicated project management

Kardex has dedicated project managers committed to working side by side with you through system concept, design and installation.

Guaranteed installation & ramp up support

We don't leave after your AutoStore system goes live. We will be onsite during the installation and ramp up phase to ensure a smooth transition for you and your team.

Local ongoing support & maintenance

Using our extensive nationwide service and support network, you'll be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

StoreX Calculator: The AutoStore Cost & Performance Tool

Provide your data inputs below to generate an estimated ROI, overall system footprint, performance metrics, storage capacity, labor requirements, and annual cost savings.

.jpg)