AutoStore Robotic Cube Technology

Calculate Your ROIUnlock your potential with AutoStore robotic cube technology

-

Fastest fulfillment

per square foot

-

Scalable processes

to manage fluctuating demand

-

Expand capacity

up to 400% without moving

Fastest fulfillment

per square foot

Scalable processes

to manage fluctuating demand

Expand capacity

up to 400% without moving

Why AutoStore?

- Efficiently managing extensive inventories with thousands of diverse SKUs.

- Maximizing warehouse space to avoid physical storage limitations. Addressing ongoing labor shortages and workforce constraints.

- Enhancing order picking speed and accuracy, particularly during peak demand periods.

- Overcoming scalability issues as inventory expands and business grows.

- Reducing energy consumption and minimizing the carbon footprint with more sustainable technologies.

- Mitigating risks associated with single points of failure, ensuring uninterrupted system operations.

- Handling significant surges in inventory levels and order volume during peak seasons without compromising performance.

- Improving ergonomics by reducing the need for employees to walk long distances and lift heavy items.

- Adapting to facilities with unconventional layouts that are not compatible with traditional storage systems.

- Retail / general merchandise

- Small parts fulfillment

- Kitting and assembly processes

- Limited warehouse space

- High SKU variety

- Automation-first operations

AutoStore excels in efficiently managing inventory with medium to high throughput levels, making it well-suited for order fulfillment of light industrial manufacturing components, hardware pieces, plumbing supplies, sensors, electrical components, and items of similar size.

- Light industrial manufacturing supplies

- Hardware components

- Plumbing supplies & valves

- Clothing & apparel

- Electrical components & sensors

- Medical devices for kitting

- Automotive parts & pieces

AutoStore empowered by Kardex

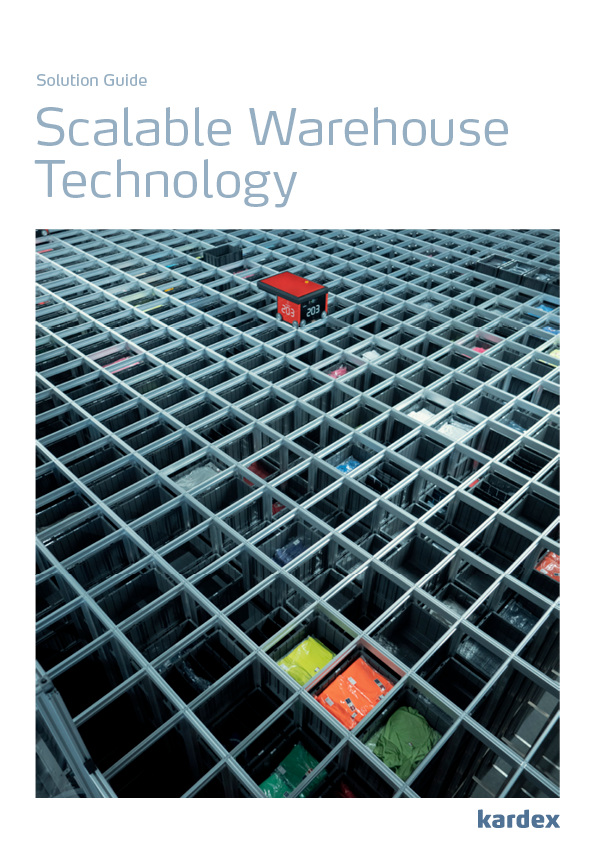

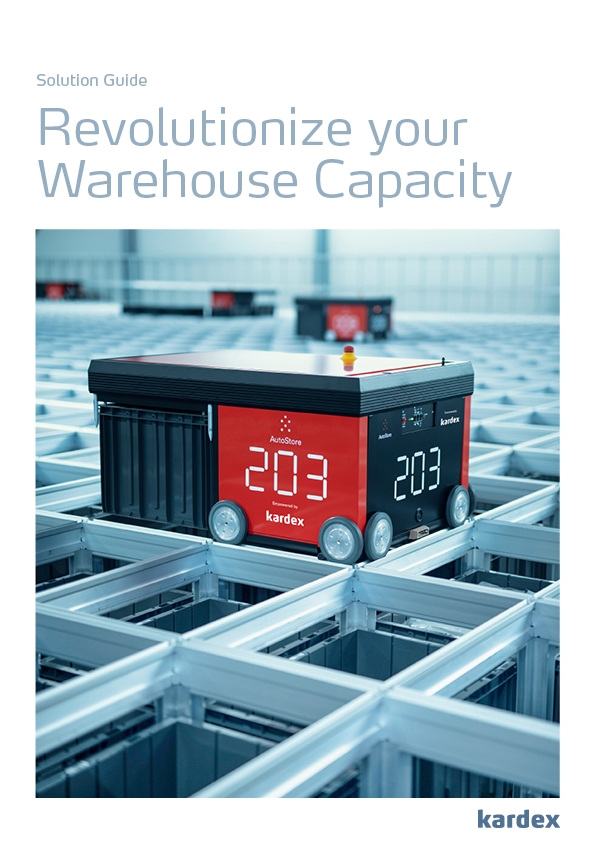

AutoStore is the fastest order fulfillment system per square foot in the market. The system is operated by autonomous robots that move on top of an aluminum cubic grid. Within this grid, storage bins are stacked on top of each other. The robots continuously pick up, rearrange and deliver bins directly to connected ports for order picking and replenishment. Designed to handle any kind of small parts, these high-speed robots are redefining manufacturing, warehousing, retail and distribution operations worldwide.

With a modular design, AutoStore systems can easily be expanded without impacting ongoing operations. The flexible grid system maximizes storage density, enabling the inventory to be quadrupled in the same space compared to conventional systems. With a global average availability of 99.6%, AutoStore is the most efficient and reliable storage system in the world.

Innovations to empower your AutoStore

Tab Navigation

FulfillX Software

Kardex FulfillX is purpose built to minimize the number of AutoStore robots required to achieve your performance but also to simplify the operator experience. Built on a modern technology stack, including a micro-service architecture and artificial intelligence, that enables optimization throughout the entire system lifespan and for future growth.

Intuitive Picking Assistant

The Intuitive Picking Assistant elevates picking processes of AutoStore™ Solutions to the next level. By projecting all relevant picking information, it guides the operator through the picking process.

High-picking performance and quality are essential in the picking process, facing challenges like labor intensity and inefficiencies. The Intuitive Picking Assistant, compatible with a wide range of AutoStore Ports, elevates AutoStore™ Solutions, streamlining operations and reducing errors.

This integration offers a scalable solution to meet the evolving needs of warehouses, optimizing efficiency and accuracy in picking processes, and addressing the challenge of finding highly trained workers.

Sensor cleaning station

Affixed to the top of the grid, the sensor cleaning station utilizes compressed air to automatically remove dust and debris from AutoStore robot sensors as the robot positions itself over top

of the station.

- The net cleaning time is only 1-2 seconds per robot

- Routine, automated cleaning keeps your AutoStore running at peak performance.

Robotic picking from bins

To operate the AutoStore ports fully automatically, we can integrate high-speed pick and place robots. These robots can pick to several locations: pick to a tote, pick to belt, pick to pallet, consolidation and replenishment.

Access technical details about AutoStore

Gain access to detailed technical information including how the robots operate, various port options tailored for functionality and speed, bin dimensions, load capacities, and much more.

.jpg)

StoreX Calculator: The AutoStore Cost & Performance Tool

Provide your data inputs below to generate an estimated ROI, overall system footprint, performance metrics, storage capacity, labor requirements, and annual cost savings.

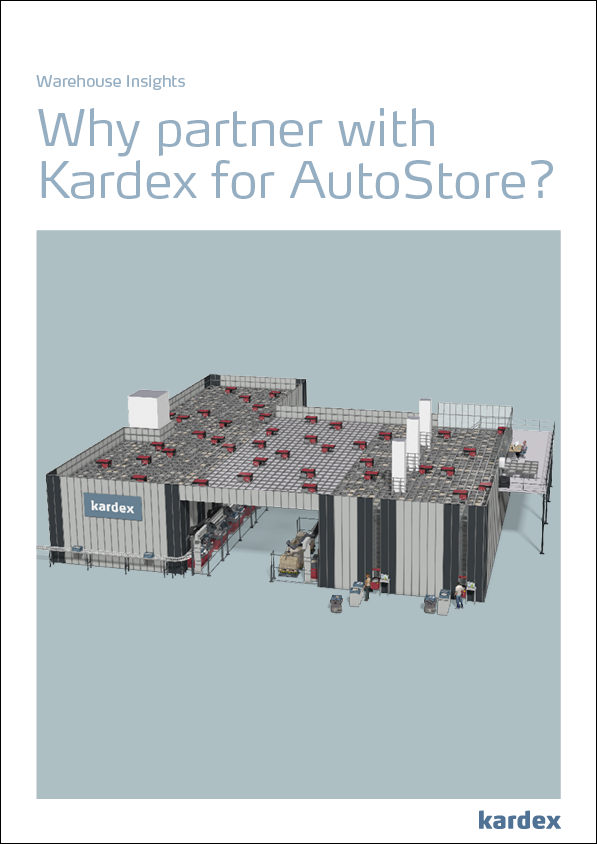

Evaluating an AutoStore integration partner

Tab Navigation

Design capability

Desired quality: The ability to design solutions tailored to the specific needs of your operation, rather than offering a one-size-fits-all approach.

How to evaluate: During the initial consultation, evaluate their understanding of your operational requirements. Do they offer adaptable solutions that grow with your business? Review their previous projects to see how they have customized solutions for other clients.

Why Kardex: We don’t believe in one-size-fits-all solutions. At Kardex, we design AutoStore systems tailored to your specific operational needs.

Take our partnership with Cutter & Buck, for example. They required a solution to handle both blank and embroidered items efficiently. We customized their system by dedicating specific ports to different tasks—some exclusively for picking blank items, others for picking SKUs and sending them to embroidery. This eliminated operational overlap, allowing operators to focus on one task at a time, which improved both efficiency and accuracy across their fulfillment process.

Integration expertise

Desired quality: Seamless integration of new systems with existing technologies and processes, including software, hardware, and legacy systems.

How to evaluate: Ask about their experience integrating systems like warehouse management systems (WMS), ERP systems, and existing automation technology. Check for partnerships with key technology providers.

Why Kardex: With decades of experience in automation integration, Kardex has earned a global reputation for delivering seamless, efficient solutions. We as Kardex AS Solutions specialize exclusively in AutoStore solutions and integration, which allows us to focus on being the absolute best in the field. Unlike competitors who work across a wide range of technologies, our AutoStore team is dedicated to perfecting AutoStore implementations, making us your ideal partner for smooth, reliable integration.

Our modern FulfillX software enables us to connect your AutoStore system effortlessly with existing technologies like warehouse management systems (WMS), ERP systems, and other automation platforms.

Ability to scale

Desired quality: Solutions that can scale as your business grows, without major disruption to operations.

How to evaluate: Assess their ability to expand and upgrade systems over time. Request examples of how their solutions have supported growing businesses and their plan for scaling without extensive downtime.

Why Kardex: Scalability is at the core of our AutoStore solutions. As your business grows, we can easily expand your solution without causing major disruptions to your operations. Need more storage capacity? We can add more columns to increase your system’s footprint. Need faster throughput? We can integrate additional robots and ports, optimizing performance to meet rising demand.

Support services

Desired quality: Comprehensive post-installation support, including maintenance, troubleshooting, and updates.

How to evaluate: Review their service level agreements (SLAs) and inquire about their response times, remote support options, and preventive maintenance plans. Ask for references who can speak to their ongoing support quality.

Why Kardex: We don’t leave once your AutoStore system goes live. We’ll be onsite throughout installation and the ramp-up phase to ensure a smooth transition for you and your team. Additionally, we stay on-site for 30 days post-implementation to provide ongoing support. Each year, we also offer a Peak Season Readiness report to ensure your AutoStore solution can handle increased inventory and high-frequency orders during peak periods.

Why Kardex

-

Dedicated project management

Kardex has dedicated project managers committed to working side by side with you through system concept, design and installation.

-

Guaranteed installation & ramp up support

We don't leave after your AutoStore system goes live. We will be onsite during the installation and ramp up phase to ensure a smooth transition for you and your team.

-

Local ongoing support & maintenance

Using our extensive nationwide service and support network, you'll be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

Dedicated project management

Kardex has dedicated project managers committed to working side by side with you through system concept, design and installation.

Guaranteed installation & ramp up support

We don't leave after your AutoStore system goes live. We will be onsite during the installation and ramp up phase to ensure a smooth transition for you and your team.

Local ongoing support & maintenance

Using our extensive nationwide service and support network, you'll be fully supported throughout the lifecycle of your AutoStore system, even in the most remote location.

Customer Stories

Justify your investment in AutoStore

Calculate your ROI, your annual labor cost savings, and learn how to reduce your storage footprint up to 4X, allowing you to expand other operational areas without moving facilities.