Improve Your Order Fulfillment Process: A Guide on Strategies & Technologies

by Gary Higginbothem

The Importance of Order Fulfillment

Order fulfillment is a high priority for most organizations due to the direct impact on customer satisfaction and the labor resources order picking necessitates. Incorrect or late orders create the potential for an unhappy customer who might decide to shop elsewhere or use another vendor next time (not to mention absorbing the costs of the return handling, shipment of the replacement and associated labor to handle the return). Additionally, order picking activities typically consume 50% - 70% of a facility’s operating expenses, it’s a huge cost—one that most operations are eager to reduce.

Couple these factors with razor-thin margins and rising customer expectations (as consumer trends from B2C delivery bleed into B2B) and order fulfillment operations is quickly becoming a main focus of most warehouse and distribution centers. With customers demanding faster, more frequent orders in smaller quantities with custom labeling and electronic delivery tracking - many warehouses are turning to technology to help streamline and automate their order fulfillment process.

Improving Your Order Fulfillment Process

Improved Picking Speeds (Pick Rate)

Picking speed measures the amount of time it takes to retrieve the product from its storage location and place it into the order container is considered the picking speed. Picking speed is usually measured with some sort of variation of how many (parts, lines, orders) are completed in a specific timeframe (hour, day) or by number of people. The picking portion brings five different activities together —receive direction; travel location; locating the item at the pick location; item pick; and item wait/mark.

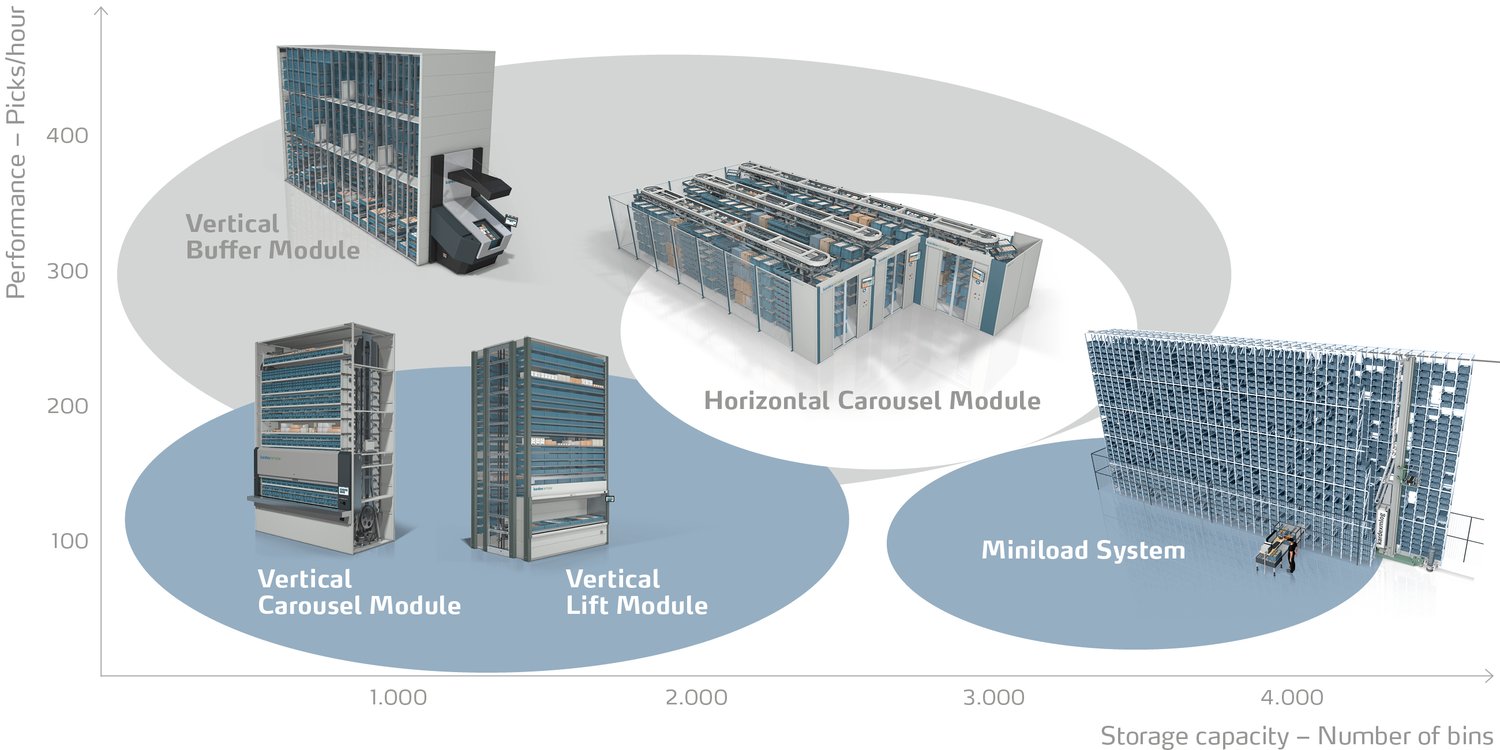

The biggest opportunity to increase picking speeds is to decrease travel time – which in a conventional, manual storage operation accounts for as much as 60% -65% of a workers time. The right picking strategy coupled with goods-to-person technologies (Vertical Carousel Modules, Vertical Lift Modules, Horizontal Carousel Modules, Multi-Shuttles and Vertical Buffer Modules) are designed to decrease walk time and increase picking speeds by delivering stored product to the operator.

Increased Picking Accuracy

Picking accuracy measures how often the correct part is picked from inventory. This can be calculated by dividing your errors by your overall picks. Some operations measure put accuracy separately; or combine pick and put into one general accuracy metric. These accuracy metrics can be expressed by line, pick or order depending on what makes sense for your operations. Technologies that assist an operator in locating the correct part (pick to light, voice directed, weigh scales, bar code scanning) are designed to improve accuracy rates within a manual or automated order picking operation.

For a Deep Dive: 5 Tips to Improve Order Picking Accuracy

Reduced Labor Costs

Understanding the Order Fulfillment Process

So now that we know why order fulfillment is crucial and the metrics we're trying to improve, let's dive into the 5 basic steps to pick, pack and ship orders quickly and efficiently (while making sure delivery meets the customer’s expectations). The secret to highly efficient order fulfillment is to organize, manage and synchronize these processes.

Receiving

Putaway/Storage

Order Picking and Replenishment

When orders are received, the inventory management software determines the best path for the operator to travel to retrieve the required items based on their storage locations. Order picking might be as simple as an associate pushing a cart to each storage location and retrieving the required quantity of each item as they follow an assigned path.

More advanced picking operations divide their warehouse into zones utilizing a picking strategy (pick and pass, zone picking with consolidation, wave picking) usually with different technologies in each zone (mini-loads, robotic shuttles, Vertical Buffer Modules, Vertical Lift Modules, Vertical Carousel Modules, Horizontal Carousel Modules, rack, shelving) to get the productivity and throughput rates they require. The most automated operations utilize robots to pick required items.

Forward pick zones (also called pick faces) are for the fastest moving individual products and might include flow delivery racks or an automated system presenting a storage tote to an associate to pick from. When a pick face is depleted of inventory, items are replenished (brought forward) from reserve storage areas elsewhere within the facility. This ensures that pickers can continuously select required items without having to leave their assigned zone.

Sortation

Packing and Shipping

- Individual items are manually placed or automatically inducted into shipping cartons or pouches. Picked items are consolidated into an order box with proper documentation, then moved on to manifesting for outbound shipment.

- Cases are palletized, stacked on a pallet and secured with stretch wrap, banding or other containment method. Items bound for replenishment of a retail store might be placed into reusable plastic totes for shipment.

- Picked pallet loads are delivered to this area by forklift or conveyor, then loaded directly onto the back of an outbound trailer.

All outbound orders are labeled with information about the shipping destination and then sorted by carrier (freight, USPS, common carrier, courier service, etc.) at the shipping dock where they are picked up and routed to the customer.

For a Deep Dive: What Is an Order Picking Process?

Best Practices for Optimizing Your Order Picking Operation

Whether your operation is a warehouse for raw materials and work-in-process storage used to feed a production line, or a distribution center (DC) storing finished goods that are picked, packed and shipped to replenish stores or fulfill individual customer orders, there are a number of order picking best practices. Implementing one (or more) of the following 15 process refinements supports higher accuracy, increased productivity, greater throughput, and faster cycle times in order picking—ultimately maximizing efficiency while boosting recipient satisfaction.

Warehouse Organization - Facility Flow

Organize your warehouse based on the order in which inventory travels through each functional area.

Establish a Receiving Process

Be sure to establish a receiving and inspection process that includes greater visibility into shipments, their contents and their scheduling, as well as more communication with dock staff about each shift’s activities and expectations.

Utilize Bins, Totes and Dividers

Whether it’s stored in on shelves, rack or in an automated system, sub-dividing inventory with reusable plastic bins, totes and dividers makes it easier to find what you’re looking for faster.

Reduce Walking Time

Properly arrange and slot your facility, and store items that are frequently picked together close to each other (staples and staplers, shampoo and conditioner, etc.) to reduce walking time.

Improve Ergonomics with Goods-to-Person Technology

Adding cushioned floor mats at locations where associates will be stationed on their feet for long periods of time; increasing frequency of training on how to lift and handle loads; and placing frequently picked items in the “Golden Zone,” or waist-high, reduces the risk of injuries associated with reaching, pulling, bending or stooping.

Utilize Light-Directed Technology

With the addition of light-directed or voice-directed picking systems, associates can more quickly find and pick the correct item in the right quantity, increasing productivity and pick accuracy.

For a Deeper Dive: 5 Pick to Light Technologies for Laser Accuracy

Integrate Scan Verification

Use automatic identification and data collection (AIDC) technologies, such as handheld or fixed-location radio frequency (RF) scanners or camera-based imagers (instead of manual methods) instantly validates an item based on its barcode.

Prioritize Timely Replenishment

Timely replenishment of forward pick zones and fast moving, frequently picked items should be scheduled throughout the day.

Implement ASRS to Reduce Costs

Investing in an automated storage and retrieval system (ASRS) typically pays off in roughly 18 months because Vertical Buffer Modules, Vertical Lift Modules, Vertical Carousel Modules and Horizontal Carousel Modules deliver a variety of cost saving benefits.

For a Deeper Dive: How to Calculate (and Reduce!) Your Fulfillment Costs per Order

Continuous Inventory Profiling

With insight into the speed with which individual SKUs in your inventory move and in what quantity, you can properly slot—or group and locate—the items in the right area and storage medium.

Establish a Returns Management Process

Establishing a process for handling those returns is critical. This should include a designated area and quality control team to receive, unpack and inspect the items, then assign each a disposition classification.

Establish Key Performance Indicators (KPIs)

Use key performance indicators (KPIs) and metrics, such as space, throughput, accuracy and labor, to benchmark your operations and identify areas for improvement.

Choose the Correct Picking Strategy

Choosing the right picking strategy for your operation—other than one person picking one order at a time—will speed up order fulfillment because it allows more picks to be completed simultaneously.

Pick Directly into Shipping Cartons

Specifically for e-commerce applications, instead of picking required items into reusable plastic totes routed to a consolidation or pack-out station, pick some—or all—orders directly into shipping cartons.

For a Deeper Dive: Optimize the Pick and Pack Fulfillment Process

Utilize a Consolidation Area

Operations using any form of zoned picking—where individual items for multiple orders are picked simultaneously—will also need an area for sortation and consolidation of the picks into discrete orders.

For a Deeper Dive: 15 Best Practices for Optimizing Your Order Picking Operation

Warehouse Order Picking Technologies

There are so many order picking technologies available to support inventory management and order fulfillment tasks—ranging from fairly simple to highly automated. No matter the solution, the basic elements of the order picking system are the same. At their most fundamental, these systems support associates and the facility in the identification, tracking, verification, organization, storage, location, sorting and handling of inventory. With so many options available, how do you know what you really need? It comes down to five fundamental technologies and making them work together.

Inventory Management Software. Software is the brains of the system—it keeps records of all the individual SKUs, their quantities and their storage locations as they enter, move within and exit the warehouse or distribution center.

Storage Systems. Used to physically store goods, there are many different storage systems available, from static to automated storage and retrieval systems (ASRS) that present items to operators in a goods-to-person methodology.

Transport Systems. The next piece to consider is how to move the product throughout the warehouse. Ranging from manual to highly automated, these include pallet jacks, lift trucks, and automated robots and guided vehicles

Automatic Identification and Data Capture (AICD) Systems. These technologies are designed to automatically collect data from an object and transfer it into a computer system, without manual data entry. These systems include bar code scanners and RFID systems.

Pick Indicator Systems. Pick indicator systems help operators quickly and accurately locate required items. They direct the operator to a specific location and provide information for the task to be completed. Pick indicator systems are paperless and allow the operator to work hands-free result in extremely high accuracy rates, reduced training time and faster picking speeds. Types of pick indicator systems include:

-

- - Pick to Light: pick-to-light and put-to-light systems are a series of modules with colored lights and (sometimes) alphanumeric displays mounted to the face of a storage location or pick destination (such as on a put-wall or tiered picking cart).

- - Voice Directed Picking: voice-picking systems consist of a wearable headset where the operator is told by a computerized voice (in his or her native language) what item to pick and how many. The operator confirms the pick by speaking back into the headset.

- - Vision Directed with AR Glasses: operators are guided through the picking process by information displayed on wearable smart glasses (such as Google Glass or VuzixM100) including production location, pick quantity and put placement. This developing technology is starting to make its way into warehouses globally.

Combining these five elements will create an order picking system. The challenge is making them all work seamlessly together and continuously tweaking the system for the best efficiency.

For a Deeper Dive: 5 Fundamental Technologies of an Order Picking System

Glossary of Order Picking Terms

Automatic Guided Vehicles (AGVs): Computer controlled, wheeled load carriers that navigate on-board or towed loads throughout a facility autonomously. They can be used to follow a picker who places picks onto a pallet transported by the AGV, for example.

Autonomous Mobile Robots (AMRs): Computer controlled and smaller than AGVs, AMRs transport smaller loads throughout a facility autonomously. They can be used to transport static shelving holding inventory from storage locations to pickers, or to transport picked items from one location to another.

Barcode Scanning: Barcode labels are very common and can be scanned by handheld or fixed-location radio frequency (RF) scanners or camera-based imagers to instantly validate the information the code contains, then transmit that data another system for processing and use (such as triggering pick indicator systems).

Batch Picking: Grouping orders together into a single picking activity to optimize productivity by allowing one picker to select all items within a predetermined group with one trip through the pick path. Batch picking requires a storage method, a batch station and inventory management software. Learn More

Bins, Totes, Containers, Cartons, Case: A vessel for storing goods/parts/items. Learn More

Broken Case: An open case of product, usually a case of inventory that has been opened and items removed likely to fulfill orders. Learn More

Buffering: The process of holding additional inventory to account for variations in your supply chain and limit the impact on your operations. Learn More

Case Picking: Filling orders with full packaged cases for shipment. Commonly stored on pallet locations. Learn More

Color Pick System: a light directed picking technology designed to work with a pod of ASRS. Orders are set up with a designated color on a workstation or cart. Workers are assigned a color to pick and they follow their color through the picking process. Color picking helps flex labor to meet demand.

Consolidation Zone: a dedicated zone in a warehouse to combine items/orders into shipping containers for shipping. Learn More

Conveyor: Fixed transport systems, conveyors can be oriented horizontally, vertically or on an incline, moving loads ranging from individual products to cases to full pallet loads from one area to another within an operation. Typical picking applications include placement between pick zones for transfer of pick totes from one picker to the next, to transport completed picks to consolidation and pack out, and from packaging to shipping docks.

Cross Picking: Two pick zones – usually comprised of automated storage units – are face-to-face. A batch station is located in between the two pick zones consisting of a side-by-side roller conveyor with a series of alternatively angled flow racks (also called slides) on top. Atop the conveyor and beneath the slides sit two rows of order totes, back-to-back – one for each pick zone. The entire system is light-directed. Learn More

Horizontal Carousel Modules: Consisting of highly dense storage bins mounted on an oval track which rotates horizontally to deliver slow- to medium-moving product storage locations to an operator, these automated storage and retrieval systems handle both items and cases weighing up to 200 pounds. To generate maximum picking speed and throughput, they are often installed in groups, known as pods. Quick Facts PDF

Inventory Management Software: A software application designed to work in coordination with automated storage and retrieval systems to manage the inventory within the system, tracking storage location, quantity, part dimensions, etc.

Kitting: the gathering of component parts and sub-assemblies into kits to supply all necessary items as one package. Learn More

Mini- and Micro-Load ASRS: a crane-based, smaller version of a Unit-Load ASRS handling correspondingly smaller, lighter loads, typically held in trays, reusable totes or cartons.

Order Picking: Order picking or order selection is the process of retrieving individual items (from storage locations) for the purpose of fulfilling an order for a customer. Order picking cannot be achieved without the appropriate software and equipment, including the storage medium, such as pallet racks, shelving and ASRS, as well as a means for transporting items from receiving to storage and from storage to packaging and shipment.

Parallel or Zone Picking: Workers are assigned a zone to fulfill orders in parallel. Each worker picks items required for an order from their zone and sends the partial order to a consolidation area.

Pick and Pass: an order picking strategy where items for an order are picked from one zone into a tote. The tote is sent to the next zone by either conveyor or manual delivery until it has been to all zones and the order picked is complete and ready to be sent to packing and shipping.

Pick to Light: A light directed technology used to reduce paper pick lists and increase pick accuracy. Learn More

Radio Frequency Identification (RFID): Information is coded into a small tag or label using an integrated circuit and antenna. Data is then captured by an RFID reader using radio waves and transferred to a host data system. Unlike barcodes, data from an RFID tag can be captured without line-of-sight.

Robotic Cube Storage: All inventory is placed into bins and stacked inside a cube. Smart robots work at the top of the cube to shuffle, sort and retrieve bins and deliver them to a workstation (port) as needed.

Robotic Shuttles: Handling cases, totes or trays, this ASRS utilizes independently moving robotic shuttles inducted into the system. The shuttles travel independently from level to level, riding on narrow rails at each storage level to retrieve stored items at high speeds.

Split Case Order Picking: A process used to fill orders by picking quantities less than a case, requiring items to be removed from a full case and picked into a smaller container for shipping or delivery. Learn More

Unit Load ASRS: Machines that automatically store and retrieve pallet loads from long, narrow aisle of storage rack with a telescopic, crane-based device that travels to and from specific storage locations.

Vertical Carousel Module: Comprised of a series of carriers attached to a chain drive, a motor powers the carriers’ bi-directional travel in a vertical loop around a track—similar to a Ferris wheel. These automated storage and retrieval systems deliver slow- to medium-velocity items safely and quickly to an ergonomically positioned work counter at the operator’s command. Quick Facts PDF

Vertical Lift Module: The most flexible technology in this category, the vertical lift module is engineered to automatically adjust when your inventory changes. With trays capable of handling up to 2,200 pounds, these enclosed dynamic storage solutions consist of two columns of trays with an inserter/extractor in the center. The inserter/extractor automatically locates and retrieves stored trays of slow- to medium- velocity items from both columns and presents them to the operator at a waist-high pick window at rates from 125 to 475 items per hour. Quick Facts PDF

Vertical Buffer Module: The vertical buffer module is an enclosed shelving system with a movable mast running down a center aisle for picking and storage of totes. This bin handling system is designed to be able to work ahead of the operator and queue up the next pick for maximum throughput of the system. Totes can be delivered to an ergonomic turntable picking station or can be automatically handled via inbound and outbound conveyor. Multiple units can be connected via conveyor and totes can be delivered to remote picking stations. The system is designed to be modular, scalable and highly energy efficient. Quick Facts PDF

Voice Picking: Voice picking systems consist of a wearable headset where the operator is told by a computerized voice (in his or her native language) what item to pick and how many. The operator confirms the pick by speaking back into the headset.

Warehouse Management System: Software used to support and optimize a warehouse’s day to day operations - from inventory acceptance, to storage, to picking, packing and shipping.

Wave Picking: Instead of picking complete orders, workers are picking lines to be sent to a consolidation zone to be combined into orders for shipping. This is a fast picking strategy and allows you to flex labor as needed. Learn More