Intralogistics for dairy plants

A dynamic market demands automated solutions

Since the removal of EU milk quotas in 2015, the economic viability of dairy plants depends now more than ever on their organic growth and on efficient processes in fresh food logistics. The trend is towards greater production and storage capacities at central locations in order to meet retailers’ high expectations with regard to flexibility and delivery capability. This requires increasingly automated intralogistics solutions.

How-to-guide: In 3 steps to optimized material flows

Optimal food storage and, in particular, dairy storage requires extensive knowledge in a number of areas: These include seasonal fluctuations, temperature and hygiene regulations, as well as individual product properties and the requirements of the entire product range. To ensure optimized material flow, you should choose intralogistics experts who can work together with you to manage these complex challenges. Benefit from the experience gained in numerous other projects within your industry!

Case studies: Warehousing in the dairy industry

The framework conditions for intralogistics are changing constantly: Extended product ranges, increasing demand or new sales channels lead to changed requirements on the material flow. This situation calls for detailed analysis and well considered decisions. Is automation the way to go? Is it time to implement new solutions? Find out how Kardex optimizes the intralogistics of dairy plants.

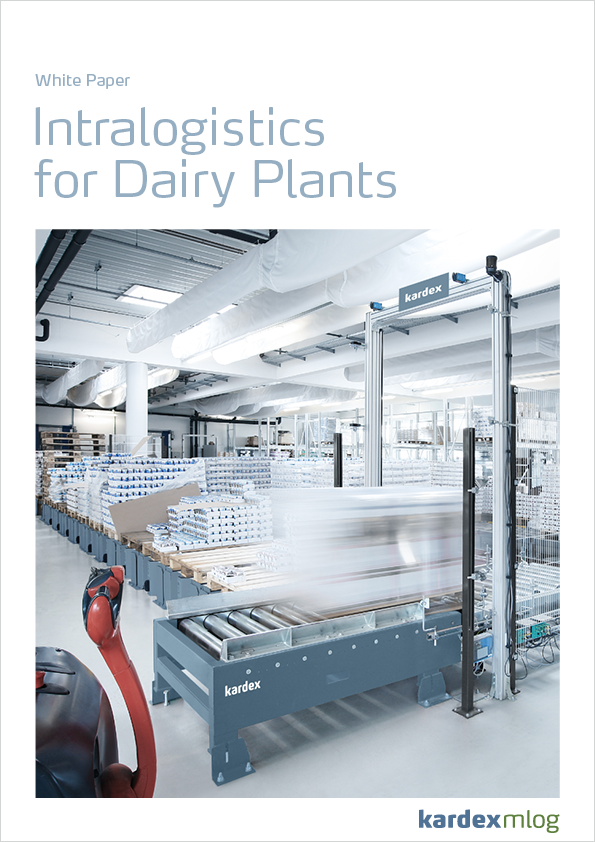

White Paper: Intralogistics for dairy products

With increasing diversity of products and containers and the trend to larger production and storage capacities at central locations, dairy companies are being forced to rethink their traditional storage concepts. Kardex Mlog takes an in-depth view of the challenges facing the dairy industry and identifies solutions that work.

Support & Life Cycle Service

Kardex knows how much warehouse operators rely on fast and reliable maintenance. For this reason, we offer several, modular service contract options, which meet the precise requirements in each case. This service is based on our competent technicians, who undergo regular training in the Kardex Academy.

The Kardex Team works hard to avoid unnecessary downtimes and to ensure that logistics plants achieve their maximum potential throughout their entire life cycle.