High-Density Automated Storage Reclaim space and boost efficiency with dense, automated storage

Increase your storage capacity, maximize space utilization, and reclaim valuable floorspace in your warehouse.

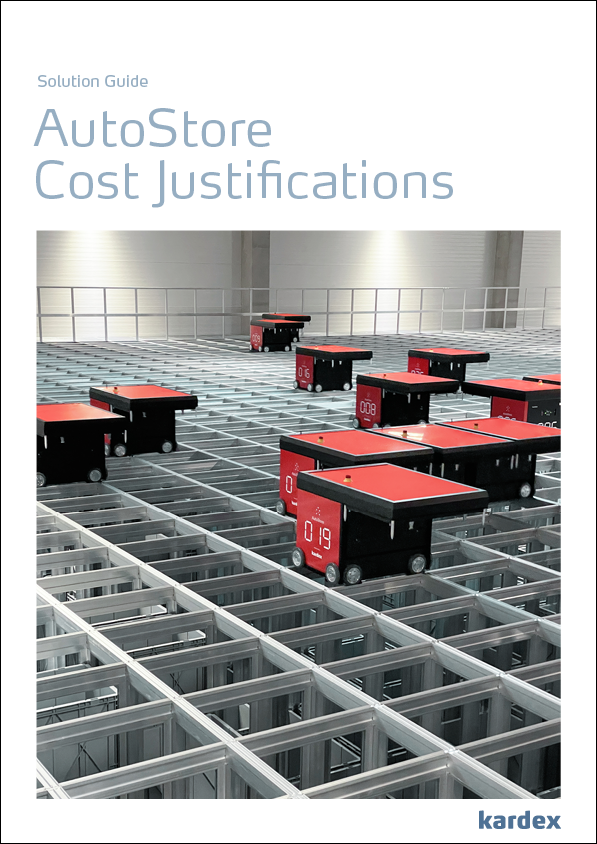

Struggling with limited warehouse space? We get it. Many facilities lose valuable space to aisles and traditional layouts that limit productivity. AutoStore’s high-density cube design can reclaim up to 80% of that wasted area, letting you store more inventory in your existing warehouse.

-

Increase Capacity 4X

Store up to 4X more in the same footprint as traditional storage

-

Reclaim 80% of Space

Free valuable floor space with high-density cube storage like AutoStore

-

Use 99.6% of Cubic Space

Bins stack densely in the AutoStore while robots travel on top of the grid

Increase Capacity 4X

Store up to 4X more in the same footprint as traditional storage

Reclaim 80% of Space

Free valuable floor space with high-density cube storage like AutoStore

Use 99.6% of Cubic Space

Bins stack densely in the AutoStore while robots travel on top of the grid

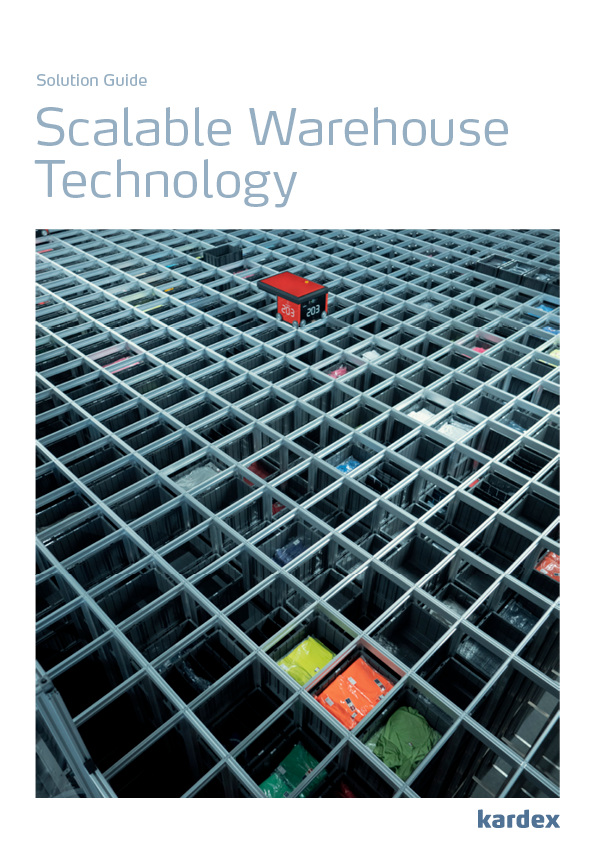

What is AutoStore?

AutoStore is the world's fastest automated storage and retrieval system per square foot.

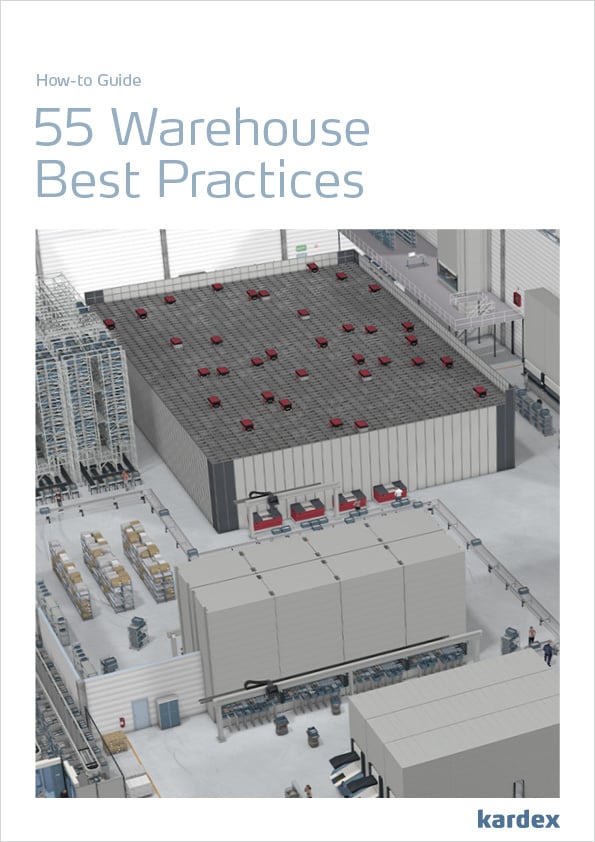

AutoStore is an automated storage and retrieval system designed to make better use of your warehouse space. By stacking bins directly on top of each other in a dense cube, it eliminates the gaps and aisles required by traditional racking and other AS/RS solutions, maximizing every cubic inch of your facility.

With Kardex’s intelligent cartonization tools, storage density can be optimized even further to fit your unique inventory mix. Robots travel on top of the grid to quickly retrieve bins and deliver them to operators, reducing walking, speeding up picking, and improving overall efficiency.

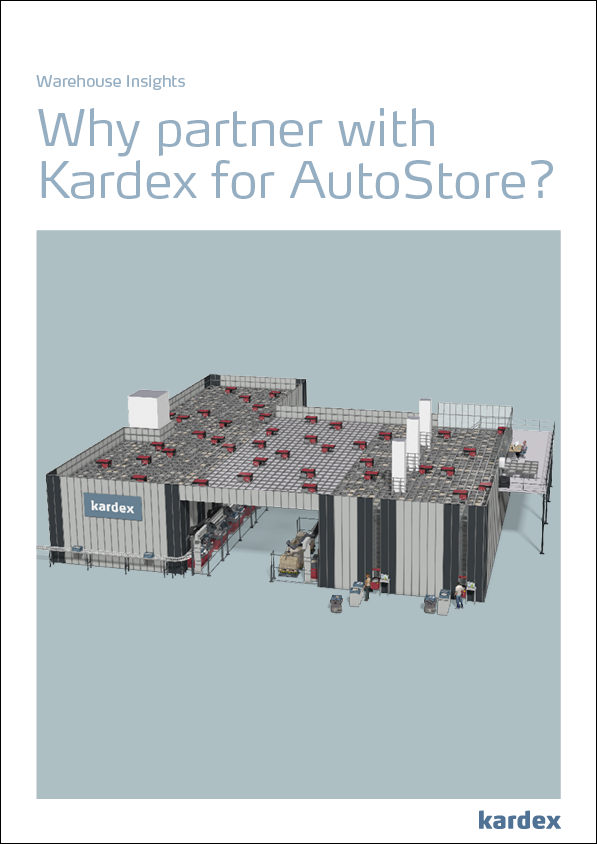

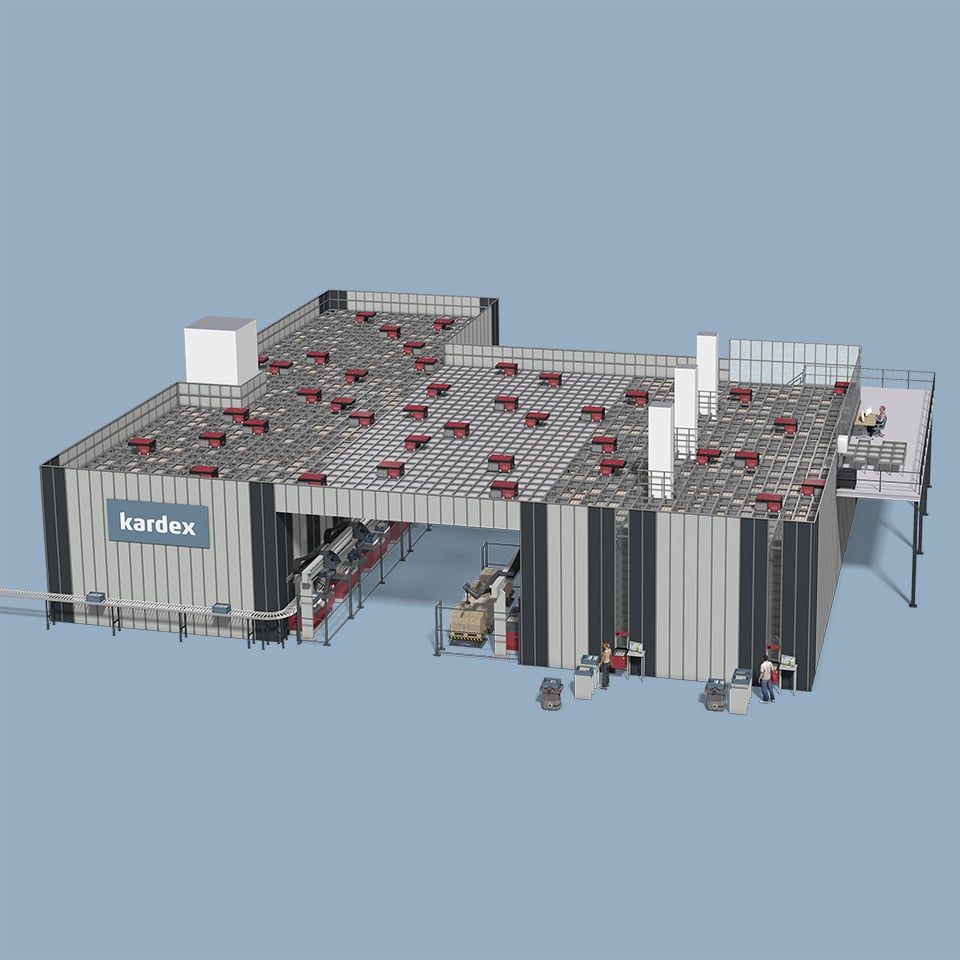

Maximize Your Storage Capacity & Productivity

Boost storage capacity by up to 4X, avoid costly expansions, and make smarter facility investments—all with AutoStore’s high-density automated system.

.jpg)

More Features & Benefits

-

Store More SKUs

Increase storage capacity by up to 400% in your current space — no new facility or racking required

-

Pick Faster, Ship Sooner

Achieve single-minute order fulfillment with the fastest ASRS per square foot, enabling true same-day shipping

-

Do More with Less Labor

Minimize manual handling and cut labor costs with a system that requires significantly fewer picking operators

-

Configure Around Your Operation

Build around columns, mezzanines, or tight footprints with a fully modular grid

-

Stay Running, Always

With 99.8% uptime, AutoStore is one of the most dependable systems in the industry — built for 24/7 performance

-

Scale at Your Pace

Adapt or expand anytime — AutoStore grows with you, without disrupting daily operations.

Store More SKUs

Increase storage capacity by up to 400% in your current space — no new facility or racking required

Pick Faster, Ship Sooner

Achieve single-minute order fulfillment with the fastest ASRS per square foot, enabling true same-day shipping

Do More with Less Labor

Minimize manual handling and cut labor costs with a system that requires significantly fewer picking operators

Configure Around Your Operation

Build around columns, mezzanines, or tight footprints with a fully modular grid

Stay Running, Always

With 99.8% uptime, AutoStore is one of the most dependable systems in the industry — built for 24/7 performance

Scale at Your Pace

Adapt or expand anytime — AutoStore grows with you, without disrupting daily operations.

How AutoStore Works

Tab Navigation

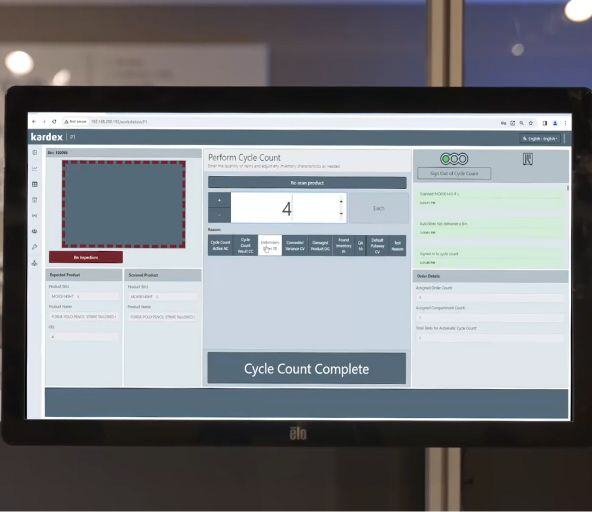

Ports

AutoStore ports are ergonomic workstations where operators handle picking, replenishment, and other inventory tasks within the AutoStore system.

There are several types of ports available, allowing for flexible integration based on throughput needs and facility layout. The the most widely used and popular port is the CarouselPort™.

Paired with Kardex’s Intuitive Picking Assistant (IPA), ports guide users with visual cues and real-time feedback to boost speed, accuracy, and training efficiency.

Grid

The aluminum grid is the structural backbone of every AutoStore system, supporting high-density vertical storage while enabling AutoStore robots to travel across the top in X and Y directions for fast, precise bin retrieval.

- Stack up to 26 levels of bins, depending on height (220 mm, 330 mm, or 425 mm).

- 220 mm bins: up to 26 levels

- 330 mm bins: up to 18 levels

- 425 mm bins: up to 14 levels

- Fast-moving items are stored near the top for quicker access.

- Modular grid fits around columns, over walkways, and across multiple levels.

- Expand anytime without interrupting operations.

Bins

The AutoStore ASRS uses durable, stackable bins to create a compact, high-density storage solution — ideal for operations with a high number of SKUs. A typical system holds around 34,000 bins. Bins can store a single SKU or be subdivided into up to 32 compartments for greater efficiency.

Managed by software and retrieved by AutoStore robots, each bin is tracked in real time for accurate, efficient inventory control. With Kardex FulfillX software, bin configurations can be adjusted dynamically — giving you the flexibility to adapt as your inventory evolves.

Bins are also available in ESD-safe options for sensitive components and can accommodate standard KLT boxes for added versatility.

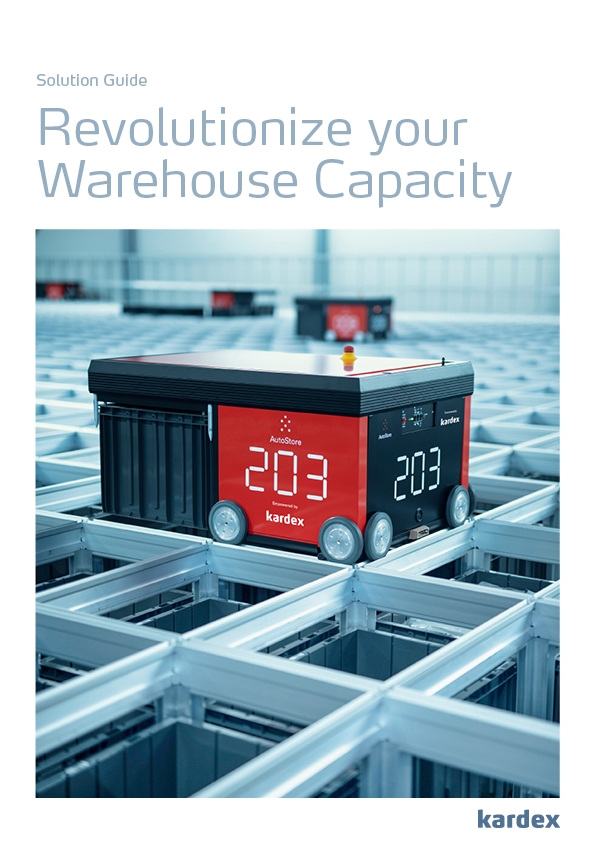

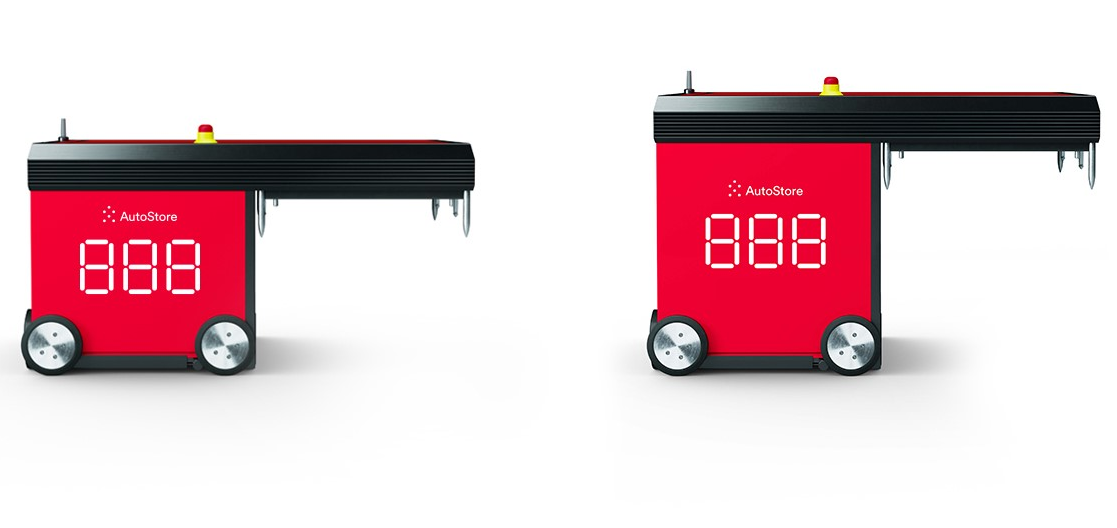

Robots

AutoStore robots retrieve inventory by lowering a lift into the grid to access the correct bin, temporarily relocating any stacked bins above it — a process known as “digging.” Once retrieved, the bin is securely transported across the grid to a designated port for operator or automated handling.

Efficient and autonomous, the robots communicate wirelessly, self-diagnose, and recharge automatically. With Kardex’s FulfillX software, robot movements are intelligently optimized — reducing the number of robots needed by up to 20% while maintaining high performance.

Software

With Kardex, AutoStore seamlessly integrates into your existing IT landscape, ensuring smooth communication across all warehouse and enterprise systems.

Kardex FulfillX offers seamless integration with your existing WMS using standard protocols such as FTP, SFTP, RESTful APIs, HTTP/HTTPS, TCP/IP, flat files, and more—typically eliminating the need for any custom development within your WMS.

| System | System Owner | Function |

| WMS | Client | Oversees all inventory zones. Manages planning, receiving, shipping, etc. |

| Kardex | Converts WMS orders into tasks, dynamically prioritizing work and providing user-friendly interface at the Ports. *Connection bewteen WMS & Controller |

|

| Controller | AutoStore | Executes bin movements, tracks bin locations, manages robots & ports |

| Unify | AutoStore | Visualizes peformance & trends |

.jpg)